Acetone: From Lab Bench to Factory Floor

Historical Development

People started making acetone long before industrial chemists came up with modern methods. Early records from the late 1700s talk about a strange byproduct neutralizing acids and mixing with water better than most oils. Michael Faraday isolated it in the early 1800s, but large-scale production really took off during World War I. The British needed a good solvent for making cordite, their smokeless gunpowder, and Chaim Weizmann found a way to ferment acetone from corn and potatoes. After that, industries grabbed hold of chemical synthesis, moving from heat-based dry distillation of wood to converting cumene in the so-called cumene process. Each step in its history echoed the needs of different times—first laboratories, then munitions, now plastics and pharmaceuticals.

Product Overview

Every day, acetone moves through factories and labs as a colorless liquid with a sharp, familiar scent. It’s a workhorse among solvents, scooping up oil, paint, and resin, and vanishing into thin air almost as soon as it’s poured. Paint thinners rely on it, nail polish removers depend on it, and chemists value it for crystal-clean glassware. Because acetone is both cheap and effective, it keeps a steady spot in supply cabinets and shop floors around the world.

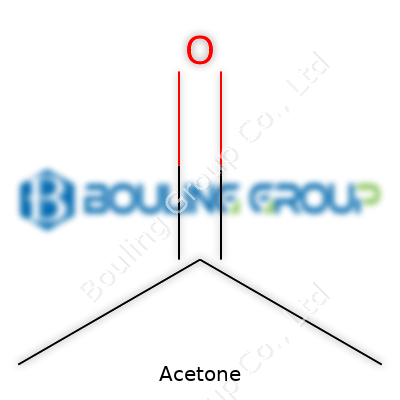

Physical & Chemical Properties

With a boiling point around 56 °C, acetone evaporates quickly—even from human skin. It mixes with water, ethanol, and most organic stuff with ease. The molecular structure keeps things simple: three carbon atoms, six hydrogens, and one oxygen in the middle. The carbonyl group at the center responds instantly in reactions, which gives this compound a reactivity that helps as both a solvent and a starting point for bigger molecules. The flammable nature is clear from its low flash point (–20 °C), and anyone handling the stuff needs to respect the risk of rapid vapor accumulation.

Technical Specifications & Labeling

Retail buyers spot acetone in quart and gallon jugs at hardware stores, but industrial buyers want certificates of analysis and a guarantee that product meets standard specifications. Typical labels mark purity above 99.5%, with trace limonene, water, and methanol flagged in parts per million. UN number 1090, proper shipping name “Acetone,” flammability warning labels, and hazard statements like H225 (highly flammable liquid and vapor) help folks stay alert and compliant with transportation and safety rules. Safety Data Sheets give details on handling, spills, and emergency steps, highlighting the need for ventilation, vapor control, and non-sparking tools.

Preparation Method

The leading factory route for acetone churns out millions of tonnes a year. Most of the supply follows the cumene hydroperoxide process: propylene from petroleum gets turned into cumene, then oxidized in air to form cumene hydroperoxide. Acid splits the hydroperoxide into acetone and phenol. This route dovetails with phenol production, making it cost-effective for chemical giants. Other routes, like fermentation or dry distillation of wood, show up in special cases or history books but can’t meet modern demand.

Chemical Reactions & Modifications

Acetone slots naturally into a bunch of chemical transformations. With strong bases, the molecule forms enolates—a gateway for building larger carbon skeletons in drugs and plastics. Reacting with hydrogen gives isopropanol, another common solvent with its own industry. Aldol reactions link acetone to itself or other carbonyls, changing structure with each new condition. In labs, chemists use acetone as a carrier to bring reactive agents together, and its volatility helps separate reaction mixtures by simple rotary evaporation. For those who want to tweak its reactivity, adding halogens or acids opens more synthetic doors. The molecule holds its own as a tool for both small-scale organic syntheses and giant chemical reactors.

Synonyms & Product Names

Every industry has its own way of labeling things. Science texts call it dimethyl ketone, propanone, or beta-ketopropane. Material Safety Data Sheets sometimes use 2-propanone. Commercial brands may list “nail polish remover” or blend it in household cleaning agents. Tracking these names matters for both supply chain accuracy and regulatory compliance.

Safety & Operational Standards

Most people catch acetone’s smell and flammability right away, but staying safe means more than knowing it will burn. The vapors spread fast and can flash-ignite with just a stray spark. Closed systems, explosion-proof fans, and grounded drums go a long way on the factory floor. Eye and face protection, nitrile gloves, and chemical-resistant clothing matter in both labs and nail salons. Local exhaust ventilation trims down inhalation risk, while regular monitoring keeps airborne concentrations well under regulatory exposure limits. For storage, cool, well-ventilated rooms away from direct sunlight are standard. Training workers in safe handling and swift action for spills can save both health and inventory.

Application Area

No industry uses acetone the same way. Paint shops depend on fast-evaporating acetone to keep brushes and sprayers free of pigment. Pharmaceutical companies turn to acetone for both synthesis and purification. Cosmetics mix it into nail polish removers, taking advantage of its ability to dissolve resins without gumming up skin. Resin and fiberglass work call for it to clean off uncured adhesives. Electronics manufacturers use it to degrease parts and remove stubborn organic contaminants. On the research end, acetone acts as a precipitation agent for proteins and a polar solvent for delicate separations. Its broad use comes from more than just price or tradition: the combination of volatility, solvency power, and simple structure turns acetone into a versatile daily driver.

Research & Development

Research into acetone stretches beyond finding new ways to make or use it. Teams study sustainable feedstocks—moving away from fossil fuels and turning to bio-based production. Early results show bacteria engineered for acetone fermentation can run on waste streams, like agricultural byproducts, opening routes for greener solvents. Analytical chemists refine methods for tracking impurities, as new regulations call for fewer toxic side products in consumer goods and pharmaceuticals. Researchers probe the physics of acetone-air mixtures, looking to curb workplace hazards or improve industrial recovery systems. Other labs model how acetone moves through soils, waters, and air, creating better ways to limit environmental risks and meet strict emission targets.

Toxicity Research

Despite how ordinary acetone seems, questions about health risks keep popping up. In the body, it’s processed and excreted quickly in small amounts. High exposure, especially in closed rooms, can bring on headaches, dizziness, and even unconsciousness. Skin absorbs some acetone, but it evaporates even faster, drying out and irritating hands, especially with repeated contact. Authorities like OSHA and NIOSH list workplace limits (usually 500 to 1000 parts per million in air), while researchers dig into long-term health risks and possible links to reproductive harm. Both government agencies and academic groups run studies, sharing their findings so regulatory limits actually line up with day-to-day experience. Reviewing that data, teams adjust safety standards for manufacturing, medical settings, and consumer use. Industry watches these trends closely, balancing risk with need.

Future Prospects

Acetone’s future points toward two big trends: green chemistry and smart manufacturing. As communities and regulators push for smaller carbon footprints, chemical companies invest in plant-based acetone routes. Improved biotechnology turns renewable feedstocks—like corn stover or algae—into the raw mix, relying on engineered microbes to spit out pure acetone. New recovery methods focus on recapturing vapors and recycling solvent streams, slashing both waste and cost. Lab work continues to tweak acetone’s basic structure, making derivatives that perform under challenging industrial conditions or show up less often in the environment. Companies join collaborations to share safety and toxicity data, aiming for safer workspaces and clearer rules. Acetone’s place in the supply chain seems safe for now, thanks in part to its nimble chemistry and history of adaptation. Most of all, scientists and manufacturers keep one eye on reliable performance and one on tomorrow’s sustainability targets.

More Than Just Nail Polish Remover

Acetone shows up in a lot of places. Most people first meet it in nail salons, where it melts away stubborn gels or glitters. But its story doesn’t stop there. Acetone has found its way into homes, hospitals, factories, and even science labs. I remember the first time I used acetone, not on nails, but to get old, sticky stickers off glass jars. It worked like magic, pulling up residue nothing else could touch.

Acetone in Cleaning and Home Use

I keep a small bottle of acetone on the garage shelf. It’s my go-to for cleaning grease from bicycle chains, stripping paint from metal tools, or even thinning super-glued fingers apart. Acetone evaporates fast, so it doesn’t leave wet messes, which makes it safer for delicate surfaces. Still, a quick wash of hands after handling is a must because it dries skin out in no time.

On the Job: Industrial Workhorse

Manufacturing plants swear by acetone. Factories use it to clean heavy-duty machines and prep metals before painting. In plastics and synthetic fiber production, acetone acts as a key ingredient—it helps break down raw materials, making everything from auto parts to packaging possible. During my college chemistry classes, acetone stood as the reliable choice to clean glassware. Unlike soap and water, it cut through oils and dried almost instantly, leaving no streaks behind.

Medicine and Science

Hospitals rely on acetone, too, including as a disinfectant or for prepping labs. Glass slides for microscope work need to be spotless, and acetone gets them there. Certain medicines and topical lotions rely on acetone as a solvent because it mixes well with other chemicals and carries active ingredients deep into the skin.

Risks and Considerations

I can’t ignore the strong smell. That chemical tang means good ventilation is necessary. Extended breathing in of acetone vapors irritates the nose and throat, and heavy exposure over time risks headaches or worse. For people at home, keeping it away from kids makes sense. Acetone can catch fire easily, so stashing it near open flames is never a good idea. In the hands of experienced workers, the risks drop—clear instructions, protective gloves, and careful storage go a long way.

Searching for Better Practices

Waste disposal matters, too. When I clean up after a paint project, I can’t just dump acetone down the sink. Local waste collection centers take used solvents, and making that drive keeps harmful chemicals out of streams and soil. Companies explore safer substitutes, like citrus-based cleaners or water-based solvents, especially in consumer products. As regulations tighten, shifting away from dangerous chemicals grows more attractive.

Looking Ahead

With all those uses, acetone reflects a balance between usefulness and caution. It handles jobs most other cleaners can’t touch. Respecting its power and risks has shaped my habits and should shape policy as well. Solutions could include moving toward safer alternatives where possible, improving packaging, and spreading knowledge about how to use and dispose of chemicals safely. Empowering people with clear information leads to better choices and healthier communities—something that matters far beyond the world of laboratory glassware or painted nails.

The Rise of Acetone in Everyday Life

Walk into any nail salon. You’ll catch the distinct smell of acetone right away. At home, people reach for it to fix smudged nail polish or clean stubborn adhesives. It’s everywhere, packed into those little bottles labeled nail polish remover. This ease means millions touch acetone every week. Yet many wonder if skin exposure brings problems.

Understanding What Acetone Does

Acetone isn’t some mysterious lab compound. The body even produces it in small amounts, especially during fasting. On its own, acetone evaporates quickly and strips oils wherever it lands. That’s why it cleans polish so well. The risk comes from how it interacts with skin, not just what it is. After scrubbing off polish, hands often feel dry and sometimes a little irritated. My thumb once cracked open after a weekend’s worth of color changes and quick removals. A dermatologist later explained that stripping away protective oils leaves skin exposed and more likely to get red or flaky.

Known Effects and Risks

Research from the Centers for Disease Control and Prevention lays it out clearly: Brief skin contact typically brings dryness or mild irritation. Those with sensitive skin may see redness or itchiness within minutes. Some studies show heavy, frequent use can even lead to dermatitis—a more severe inflammation. The solvents in industrial acetone, unlike beauty-grade stuff, carry a bigger punch. Paint shop workers who get regular splash exposure to stronger mixes develop peeling, burning, and cracking, sometimes needing medical care. It’s less risky in a home setting, but the pattern shows that regular, significant exposure stacks up over time.

One misconception deserves to be set straight: Acetone itself doesn’t cause cancer, nor has it shown to be absorbed deeply enough to reach blood in amounts that would truly threaten health from short contact. Problems come mostly from repeated barrier breakdown, not from systemic poisoning.

Safer Approaches and Alternatives

Nobody wants dry, stinging hands or accidental cuts. After my own rough patch, I started using acetone sparingly and switched to non-acetone removers when possible. Non-acetone products—often using ingredients like ethyl acetate—don’t work quite as fast but feel kinder and leave my skin less raw. Gloves reduce problems for those using acetone regularly, such as nail technicians. Moisturization makes a clear difference, too; a thick cream, not just a light lotion, helps fix the tight, chalky look acetone leaves behind.

Educators and doctors alike remind people to never use acetone on broken or inflamed skin, and always give nails and cuticles a break between uses. For anyone with eczema, psoriasis, or allergies, the risks multiply and professional guidance matters even more. No polish color justifies weeks of cracked fingers.

The Bottom Line

People depend on acetone for quick fixes and beauty routines, but direct, repeated exposure dries and damages skin. Switching to gentler options, wearing protective gloves, and moisturizing right after each use all help. By taking small steps, anyone can stay stylish without sacrificing skin health.

Why Acetone Is a Go-To for Nail Polish Removal

Most people who’ve painted their nails have met acetone at some point. You open the bottle, dip in a cotton pad, swipe, and the colorful mess goes away. The secret is simple chemistry. Acetone is a strong solvent. Nail polish, stacked with resins, pigments, and film-formers, doesn’t stand much of a chance against something as effective as acetone. The nail polish breaks down, lifts off the nail, and wipes away with almost no effort. It’s a process millions rely on, and it works even for stubborn glitter.

I’ve tried lots of alternatives—some “natural” removers, old beauty hacks with lemon juice and vinegar, straight-up scrubbing. They can work, but only after patience wears thin or the struggle becomes real, especially if you love classic reds or dark shades. Acetone clears the deck faster, and that’s why it sits in so many drawers and bathroom cabinets.

Skin and Nail Health: What You Should Know

Here’s the real punchline: acetone works, but it’s not exactly gentle. In my own experience, a weekend of party glitter nails brought lots of compliments but left the cuticles cracked and my nails dry after wiping it all off. That’s because acetone not only grabs polish but pulls moisture and oils out of your skin and nail bed. Research from dermatology journals backs up what those of us with brittle, peeling nails already know—repeated use can lead to weaker, rougher nails and sometimes irritation or redness.

Dermatologists and nail techs both talk about hydration. After using acetone, putting on hand cream or cuticle oil makes a real difference. There’s no point in using the best solvent if it leaves your hands feeling like sandpaper.

Alternatives and Safe Use Tips

Acetone-free removers use gentler solvents like ethyl acetate or propylene carbonate. They smell nicer and feel less harsh. Those work well on newer polish or less intense shades, but I’ve found heavy-duty polish or gel just laughs at them. For lots of us, the choice depends on the trade-off: quick removal versus keeping nails in good condition.

Solutions? A few make a real impact. Using acetone every now and then, not for every polish change, gives your nails time to bounce back. Apply a protective base coat before polishing, which adds a layer the remover works through first. Moisturize before and after removal—creams, oils, it all helps. Always use acetone in a well-ventilated area, since that strong smell signals both power and potential irritation.

What’s in the Bottle Really Matters

One thing stands out. Not all acetone is created equal. Pure acetone works fast but packs the hardest punch on nail health. Blended versions—like commercial removers—sometimes add aloe or vitamins to soften the blow. Checking ingredient lists pays off.

In the end, yes, acetone reliably removes nail polish. It’s one of the few products that does exactly what people expect—just don’t forget to show your nails kindness afterward. The balance between beauty and care doesn’t mean skipping the good stuff. It’s about using it wisely and giving your hands the attention they deserve.

Why Acetone Storage Is a Real Issue

Anyone who’s worked in a garage or lab will tell you: acetone doesn’t mess around. People use it to clean tools, thin paint, or remove nail polish, but the stuff evaporates quickly and catches fire with next to no effort. Forget the fancy jargon—mess up storing acetone, and you’ve got a recipe for disaster. The way acetone vapor hangs in the air can turn a tiny spark into a major incident. I’ve opened a can once and caught that cold whiff of something serious, which always sends a person hunting for a safety sheet.

Fire Risk Isn’t Just a Warning Label

Put a can of acetone on a shelf over a hot water heater, and the consequences come fast. The flash point sits way below room temperature, and just a little careless storage can leave you with a fire risk that sneaks up on you. Tanks, drums, cans—any container should be tightly sealed. Think metal, not plastic, unless you know the plastic won’t turn soft or dissolve over time. I’ve seen workshops use anything they can find, then wonder why the floor smells like trouble. Just because you bought it in a safe container doesn’t mean it stays safe if tossed around or left open.

Ventilation and Temperature Matter More Than You Think

People sometimes store acetone in a cramped closet next to supplies, then complain about headaches. A well-ventilated space pulls vapors away from your nose and from anything that can spark—tools, outlets, even static electricity. Don’t park it near heat sources or in direct sunlight, either. Heat not only pushes vapors out faster, but also raises the pressure inside the container, making leaks more likely. In my own space, I almost learned this lesson the hard way, until a dented can hissed open one summer afternoon. No one wants to air out a room because of a simple mistake.

What the Law Expects

Workplaces follow rules that keep everyone safer, like using flammable storage cabinets with self-closing doors. Cabinets line up along the back of many shops, painted bright yellow so they can’t be missed. In some cities, the fire department shows up just to check that the labels are facing out, and that the doors still snap shut. For households, the rules run looser, but the risk stays the same. Store only what fits in a small metal container, away from living spaces.

Practical Solutions That Actually Work

Never pour acetone into just any empty bottle. Buy smaller containers if you only need a bit—no use bringing home a gallon if a cup lasts a year. Label everything, even makeshift bottles, because clear liquid looks the same as water under fluorescent lights. Keep rags that soaked up acetone in a sealed metal can or dunked in water before tossing, since they can catch fire days later. Lock the stuff away from kids, pets, and anyone who doesn’t read labels.

Strong practices like these don’t just follow guidelines—they respect the power of the materials people use every day. If a process feels like overkill, keep in mind that it only takes one moment of carelessness to make safety seem obvious in hindsight. Acetone isn’t a product to take lightly, and safe storage turns a risky tool into just another job well managed.

Straight Talk About What Acetone Does

Most of us have used nail polish remover at home or worked in a school lab with the stuff. The smell of acetone is sharp and unmistakable. Plenty of folks shrug it off, never thinking much about what breathing in those fumes might do. But science doesn’t give us a free pass. Acetone isn’t just a convenience in everyday life; it’s a strong chemical that deserves some caution.

How Our Bodies Respond

Even a small whiff might trigger headaches or dizziness. Spend a bit longer in a poorly ventilated space filled with these vapors and your nose, throat, and lungs start to sting. That burning isn’t just discomfort—it’s the tissues in the airways getting irritated. People with asthma or any breathing problems feel this punch more strongly, sometimes ending up wheezing or short of breath.

Short-Term Exposure Isn’t Harmless

Acetone moves fast through our system. A bit more exposure, like working long hours around nail products or cleaning solutions, leads to nausea, confusion, and, in tough cases, loss of consciousness. The science is clear on this. Studies published by organizations like the CDC show that overexposure comes with those risks, especially if people ignore symptoms and keep working without breaks or fresh air.

Long-Term Risks Add Up

People who handle acetone on the job live with more than just short-term symptoms. Constant low-level exposure messes with the liver and kidneys. These organs filter everything we put into our bodies, and chemicals like acetone only give them more work. Researchers at the National Institute for Occupational Safety and Health remind workers that repeated exposure over years can knock these organs off balance. There have even been links to nervous system problems—memory loss, slower reaction times, and mood swings show up in folks who spend years around the fumes.

What Real Safety Looks Like

No clever marketing will make acetone safe if people use it in tiny, crowded spaces. Simple steps lower the risks. Good ventilation is non-negotiable—opening a window or running a fan pulls fumes out before they reach your lungs. Schools and salons that prioritize clean air keep their staff and students safer. Personal protective gear like masks with rated filters adds another line of defense, especially in places where windows aren’t an option.

I’ve spent time volunteering with people in trades who use solvents every day. Many develop a cough they brush off, only realizing much later that chemicals like acetone play a big part in their health struggles. Teaching them about using gloves, masks, or taking regular breaks isn’t about fear—it's about giving them the power to protect themselves.

Rethinking How We Work

Nobody likes extra rules, but when it comes to chemicals, the cost of ignoring the risks lands squarely on workers’ health. Employers and workers make better choices when they know how something like acetone can harm the body. Regulations from OSHA give guidelines, but changes happen when people on the ground take these facts seriously.

Swapping in safer alternatives works in some cases, but not every job gives that choice yet. Pressure to finish tasks fast sometimes overshadows safety reminders, so real-world solutions need to fit the way people work and live.

Bottom Line

Acetone is more than a strong smell in the air. If people respect the dangers, use practical safety steps, and speak up about unsafe conditions, it’s possible to cut down the worst effects. No one gets a free pass from chemistry, but we get to choose how much risk we take.

| Names | |

| Preferred IUPAC name | propan-2-one |

| Pronunciation | /ˈæsɪˌtoʊn/ |

| Identifiers | |

| CAS Number | 67-64-1 |

| Beilstein Reference | DXNFHNWVLWJUEM-UHFFFAOYSA-N |

| ChEBI | CHEBI:15347 |

| ChEMBL | CHEMBL153 |

| ChemSpider | 175 |

| DrugBank | DB01930 |

| ECHA InfoCard | 100.000.602 |

| EC Number | 200-662-2 |

| Gmelin Reference | 607 |

| KEGG | C00994 |

| MeSH | D000008 |

| PubChem CID | 180 |

| RTECS number | AL3150000 |

| UNII | 6MZL7U7EVR |

| UN number | UN1090 |

| Properties | |

| Chemical formula | C3H6O |

| Molar mass | 58.08 g/mol |

| Appearance | Clear, colorless liquid with a characteristic, pungent, sweetish odor. |

| Odor | fruity, mint-like |

| Density | 0.790 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.24 |

| Vapor pressure | 240 mmHg (20°C) |

| Acidity (pKa) | 19.3 |

| Basicity (pKb) | pKb = 10.4 |

| Magnetic susceptibility (χ) | −7.7×10⁻⁷ |

| Refractive index (nD) | 1.358 |

| Viscosity | 0.32 mPa·s |

| Dipole moment | 2.91 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 198.1 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -248.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1790 kJ/mol |

| Pharmacology | |

| ATC code | D07AX10 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Danger |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P233, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-4-0 |

| Flash point | -20°C |

| Autoignition temperature | 465°C |

| Explosive limits | 2.5% - 12.8% |

| Lethal dose or concentration | LD50 oral rat: 5,800 mg/kg |

| LD50 (median dose) | 5800 mg/kg (rat, oral) |

| NIOSH | K136 |

| PEL (Permissible) | 250 ppm |

| REL (Recommended) | 500 ppm |

| IDLH (Immediate danger) | 2500 ppm |

| Related compounds | |

| Related compounds |

Diacetone alcohol

Mesityl oxide Isophorone Phorone Acetone peroxide |