Benzoyl Chloride: Progress, Properties, Uses, and the Road Ahead

Historical Development

Benzoyl chloride came into the spotlight during the rise of organic chemistry in the nineteenth century. Chemists noticed its reactive chlorine group opened doors for making all sorts of benzoyl compounds. Throughout the decades, the demand for more efficient synthesis routes led to a shift from simple distillation processes to advanced controlled chlorination of benzaldehyde. As industrial chemistry grew, factory-scale production of benzoyl chloride took off around the mid-1900s, increasing its availability for both researchers and manufacturers. Older processes often produced impurities or dangerous byproducts, yet today’s facilities employ strict quality controls to limit environmental impact and ensure reliable purity. This evolution shows just how tight the relationship has been between the growing demands of science and the shape of the chemical industry.

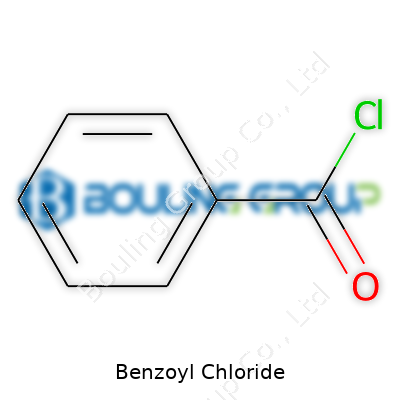

Product Overview

Clear, colorless, and sharply pungent, benzoyl chloride often appears in glass bottles protected by careful labeling. Factories and labs alike rely on it as a core reagent for making dyes, pharmaceuticals, and agrochemicals. Its formula, C7H5ClO, makes it a staple for reactions involving the introduction of the benzoyl group. Many routine products in our lives—think prescription drugs, color-fast textiles, and photographic agents—trace their roots back to a step involving benzoyl chloride. The worldwide chemical trade regards it as a commodity with strict handling guidelines, given the hazards it brings to workers and the environment.

Physical & Chemical Properties

Benzoyl chloride boils at around 197 °C with a melting point close to -1 °C. At room temperature, it gives off an acrid-smelling vapor that can sting your eyes and nose—those who've worked in a lab know its bite. It's dense, at about 1.2 g/cm3. The compound dissolves in most organic solvents but reacts vigorously with water, sending off clouds of hydrogen chloride gas alongside benzoic acid. Strongly electrophilic, the chlorine atom is quick to join up with nucleophiles, making the substance ideal for synthesizing a wide range of chemicals. Its volatility and reactivity demand good ventilation and proper gear to avoid chemical burns or toxic exposure.

Technical Specifications & Labeling

Industrial shipments of benzoyl chloride come with a clear run-down: acid chloride content must exceed 99%. Trace impurities like benzaldehyde or benzoic acid get measured in parts per million, with anything above specification raising concern. Each bottle or drum sports hazard pictograms reflecting both acute toxicity and corrosion risks. Batch numbers, manufacturing dates, and standards certifications help users trace the origin and qualify the product for critical applications. Regulations mandate child-resistant caps and secondary containment, not out of paranoia, but necessity—mishaps have led to severe injuries and fines in less-regulated settings.

Preparation Method

Producers turn to the chlorination of benzaldehyde or benzoic acid as the main route. Controlled addition of chlorine gas to benzaldehyde at cool temperatures, with or without a catalyst, sets off a transformation to benzoyl chloride, typically with purification steps to strip off any leftover chlorine or unwanted byproducts. The process involves precise control over timing and temperature to avoid forming polychlorinated byproducts. Advances in closed-system reactors and gas-scrubbing technology help curb emissions. Some companies have explored catalytic oxidative processes for greener manufacturing, but traditional methods dominate due to low cost and scalability.

Chemical Reactions & Modifications

Benzoyl chloride reacts with a broad world of compounds—amines, alcohols, phenols—giving rise to benzamides, esters, and ethers. Organic chemists rely on its readiness to hand over its benzoyl group in classic acylation reactions like the Schotten-Baumann process. Each reaction produces unique challenges involving heat control, stoichiometry, and waste cleanup since hydrochloric acid is always part of the equation. Modifications like using phase-transfer catalysts or microreactors in modern labs help boost efficiency and safety. Advances in flow chemistry are pushing boundaries even further, giving researchers greater precision and fewer side products.

Synonyms & Product Names

Benzoyl chloride answers to plenty of handles in chemical catalogs: benzenecarbonyl chloride, benzene carbonyl chloride, and artificial names from trade suppliers. The popularity of its short-hand “BzCl” has spread far beyond elite labs into university classrooms and industry seminars. These synonyms matter because international trade, safety data, and labeling standards often differ from country to country. Researchers fresh to the field learn early that missing a synonym can mean missing critical safety updates or regulatory changes for their projects.

Safety & Operational Standards

Anyone who’s worked with benzoyl chloride remembers the drill: full-face shields, neoprene gloves, and access to immediate washing stations. Its fumes cause burns on contact and can trigger severe respiratory problems. Factories devote entire rooms to handling acid chlorides, with positive-pressure air delivery and remote-activation emergency showers. Standard operating procedures call for strict storage isolation from bases and water-rich environments, which can turn a minor spill into a full evacuation. The industry leans on globally harmonized system (GHS) labeling to educate users and inspectors, reducing the risk of errors in busy warehouses and laboratories. Training is ongoing because accidents trace back to small lapses—leaky hoses, faded warning stickers, or missed personal protective gear.

Application Area

Industries use benzoyl chloride in all sorts of production lines. The pharmaceutical industry counts on it to build antibiotics, antihistamines, and local anesthetics. Dye manufacturers turn it into vivid colorants that stand up to light and washing. Agrochemical makers use it to create pesticides and herbicides that boost crop yields and keep infestations in check. The cosmetics world relies on it to synthesize UV stabilizers and preservatives, though stricter safety standards now guide usage there. Even the photographic industry, despite the digital shift, keeps a role for benzoyl chloride in specialty emulsions and reagents. Over and over, it acts as a bridge compound—essential for joining complex molecular parts into finished goods.

Research & Development

Lab teams around the world keep looking for safer, cleaner ways to use and produce benzoyl chloride. Current research focuses on reducing toxic emissions, recycling residual materials, and replacing harmful solvents. I’ve seen promising work using solid catalysts and microwave-assisted processes, which trim energy demands and leave fewer pollutants. Computational modeling speeds up the search for reaction pathways that yield fewer byproducts. In academic settings, researchers probe how to fine-tune benzoyl chloride’s reactivity, targeting more selective outcomes for pharmaceuticals where every percent of purity shaves weeks from regulatory approval. The push for greener chemistry finds a challenge in benzoyl chloride, yet each new process inches industry away from old, wasteful habits.

Toxicity Research

Toxicologists have studied benzoyl chloride for decades because it straight-up irritates the eyes, skin, and lungs, and its breakdown products include hydrochloric acid and benzoic acid. Long-term exposure raises the risk of chronic respiratory issues; animal studies point to cumulative organ damage at higher doses. Regulators in the US, Europe, and Asia have set workplace exposure limits based on these findings, and modern safety sheets spell out spill and inhalation emergencies with little room for ambiguity. Studies continue, especially with concern over delayed effects and the potential for rare allergic reactions. Better detection technology means even low-level leaks now get noticed, and the bar for allowable exposure keeps dropping, nudged both by science and worker advocacy.

Future Prospects

Expectations for benzoyl chloride in the coming years center around three things: safer production, cleaner waste streams, and less hazardous substitutes. Chemists everywhere hope for a version that does the same job with fewer risks, both for reactors and the biosphere. Green chemistry voices get louder at conferences, nudging industry players to develop new routes that swap chlorine for more benign functional groups or use renewable feedstocks. Advanced containment, digital hazard monitoring, and AI-driven process controls look set to change both lab and plant practices. Demand for specialty chemicals keeps rising with population growth and emerging tech, so the pressure lands on manufacturers to show they’ll keep up with regulations and social expectations. Benzoyl chloride has stood the test of time, but staying vital in the future will depend on embracing both innovation and tougher safety standards.

The Role Benzoyl Chloride Plays

Benzoyl chloride doesn’t show up in grocery stores or medicine cabinets, but people rely on goods that wouldn’t exist without it. This sharp-smelling liquid brings big changes to how materials behave. Companies use it to start chemical reactions that transform simple ingredients into useful things.

Everyday Products Start in the Lab

One surprising fact: benzoyl chloride helps create many plastic products. The process behind PVC production, for example, uses this chemical as a building block. Car dashboards, plumbing pipes, wire insulation—these rely on stable, weather-resistant plastics. Many of those characteristics trace their roots to small but essential chemicals like benzoyl chloride.

Beyond plastics, this chemical paves the way for dyes and paints. Vibrant colors covering walls or clothing often begin with chemical tweaks that only benzoyl chloride can pull off. Textile factories use it to get fabrics that soak up color, while paint companies rely on its reaction power for pigments that last through sun and rain.

Medicine and Beyond

Benzoyl chloride finds its way into the world of medicine, too. Some painkillers, antihistamines, and antibiotics start with a reaction involving benzoyl chloride. It doesn’t show up in the final pill or liquid, but its part in the process matters. The reason? It attaches and removes certain groups from molecules, letting chemists craft new drugs that help people heal.

People with allergies or infections might never hear about benzoyl chloride, but their treatments draw life from its use. By making it possible to tweak molecular shapes, benzoyl chloride opens the door for targeted therapies.

Safety Concerns Demand Attention

Handling benzoyl chloride takes serious care. It burns skin, stings eyes, and if breathed in, can damage airways. I remember reading about a spill at a small research lab—evacuation went smoothly because the workers ran regular safety drills, but the mess reminded everyone that not every workplace pays strict attention. Responsible manufacturers enforce airtight storage, good ventilation, and emergency showers. They train workers with clear instructions and push for tight regulation, as the consequences for ignoring basic safeguards aren’t pretty.

The Environmental Protection Agency and OSHA have set out strict guidelines, yet smaller factories sometimes cut corners, whether out of ignorance or to save money. This attitude can backfire, leading to injuries, costly fines, and, worst of all, public distrust. Industry needs to keep safety education front and center, not as an afterthought once disaster strikes.

Room for Safer Alternatives

Green chemistry keeps making headway. Labs are starting to use less hazardous chemicals, and many research teams search for substitutes that won’t put workers or the environment on the line. Companies have begun investing in research that moves away from old methods when possible, though change takes time.

Benzoyl chloride remains a key ingredient in paint, medicines, and plastics, but its dangers stick around, too. The path forward runs through better training, clear rules, and new chemistries that aim to do no harm. That’s where I see progress making the real difference—not just in what we make, but how we choose to make it.

Understanding Benzoyl Chloride Risks

Benzoyl chloride shows up in labs and chemical plants more often than folks outside those spaces would guess. This clear, colorless liquid may seem low-key, but it carries a tough reputation for a reason. It gives off acid fumes on contact with moisture and eats right through skin, eyes, or a set of gloves that isn’t rated for chemical resistance. Shortcuts with safety around benzoyl chloride have cost people their health and sometimes their lives. My chemistry professor once shared a near-miss story, reminding us that what you can’t see or smell can still hurt you fast.

Personal Protective Equipment: Not Just for Show

Lab coats and goggles work, but they are not enough. Splash goggles with side shields, chemical face shields over safety glasses, heavy nitrile or butyl rubber gloves, and long sleeves keep benzoyl chloride from reaching your skin and eyes. I’ve seen folks stubborn about this gear until one small spill changed their minds. Sturdy gloves that fit well give better control and fewer accidents. Long pants and closed shoes stop spills from trickling down to your legs or feet.

Engineering Controls Keep Accidents in Check

A fume hood takes top priority. Benzoyl chloride vapors react with water in the air, filling the room with hydrochloric acid mist. Opening a bottle under a fume hood means you’re not breathing that invisible hazard. Ventilated storage cabinets prevent fumes from leaking into work areas between uses. Corrosive-proof containers add another layer of protection; I learned this the hard way after a cracked glass bottle left me a chlorinated mess to clean.

Handling Techniques That Matter

Benzoyl chloride is fast to react with water, so always dry the work area and equipment before even opening the container. Pour slowly, aiming away from yourself and others. Using secondary trays labeled for corrosives catches any splash or drips. Never pipette by mouth, no matter how senior you think you are. Water sources nearby (including sinks) spell trouble—keep benzoyl chloride far from them to avoid dangerous hydrolysis.

Emergency Preparedness Isn't Optional

Eyewash stations and safety showers belong within arm’s reach, not just somewhere in the hall. Spills or splashes call for immediate and copious flushing with water for at least 15 minutes. You need someone nearby who knows what to do in a pinch. Safety data sheets pinned by the door are not just a formality; they show the quickest way to neutralize spills or guide first responders. Make the emergency plan a drill, not guesswork.

Storage and Disposal—Don’t Cut Corners

Keep benzoyl chloride bottles in ventilated, labeled cabinets, away from bases and water-based chemicals. Tightly sealed caps block moisture from creeping in and starting a dangerous reaction. Only use containers rated for corrosives. For disposal, never pour down the drain. Chemical waste teams should handle it, following regulatory guidelines. This avoids waterway contamination, and hefty fines, and keeps the workplace safe for everyone.

Building Safer Lab Habits

Training and thoughtful practice combine for real safety. Benzoyl chloride is unforgiving; mistakes happen faster with chemicals that don’t offer second chances. Asking questions, reviewing safety protocols regularly, and sharing stories from the field keep the work environment safe. The best labs keep close tabs on what chemicals come through their doors and treat each one with respect, not just compliance.

Understanding Benzoyl Chloride Risks

Benzoyl chloride stands out as one of those chemicals that quickly earns respect from anyone who has handled it. A colorless to pale yellow liquid with a sharp, irritating smell, this compound reacts fiercely with water and humid air, releasing heat and stinging fumes of hydrochloric acid. These qualities make it useful in industry, but also demand special care once a drum or bottle arrives on site.

Choosing a Location: Dry, Cool, and Isolated

Storing benzoyl chloride away from water may seem obvious, but you’d be surprised how easy it is to overlook cracked seals, sweaty pipes, and dripping ceilings in an industrial zone. Moisture spells trouble, so dry conditions always come first. Heat ramps up the danger. Room temperature or cooler—around 15-25 °C—helps slow down unwanted reactions and keeps volatile fumes from building up.

Facilities usually set aside a secluded area for benzoyl chloride, not just because of the smell but to isolate it from other incompatible chemicals. Mixing with strong bases, amines, alcohols, or even simple household cleaning agents can set off violent reactions. The isolation zone deserves clear labeling and strict controls, a lesson learned by anyone who has dealt with surprise leaks or accidental mix-ups.

Containers: Why Material Matters

Benzoyl chloride chews through weak containers. Glass, stainless steel, or certain hard plastics (like Teflon) offer the strength and chemical resistance this liquid demands. The container seal must be tight, not just to hold in liquid, but also to keep out humid air. Even a small breach lets in moisture, triggering fumes, pressure, and ultimately corrosive damage to the lid or drum.

Ventilation and Emergency Response

Some chemicals sit quietly and wait. Benzoyl chloride gets fidgety, especially in hot or summer conditions. Storage rooms benefit from constant ventilation. Not only does this clear away accidental vapors, but it also reduces the build-up of hydrochloric acid mist, which can eat through metal over time and cause breathing trouble for workers.

Part of safe storage means anticipating failure. I’ve seen facilities keep full chemical suits and emergency wash stations at arm’s reach. Spill kits featuring neutralizers—like sodium carbonate or calcium hydroxide—stand ready to contain a splash or puddle without delay. Alarm systems and regular training make sure the team responds quickly to leaks and knows exactly where to run.

Inventory, Monitoring, and Record-Keeping

Letting drums of benzoyl chloride pile up might save time in the short run, but big stockpiles come with bigger risks. Facilities benefit from tight inventory controls. Tracking quantities, monitoring expiration dates, and steady visual inspections stop small leaks before they turn major. Good record-keeping not only meets regulatory requirements in the US and EU, it gives workers peace of mind that unknown hazards aren’t lurking in forgotten corners of the warehouse.

Training and Culture Make the Difference

Handling benzoyl chloride isn’t just about following rules on paper. Facilities that invest in real-world training—practicing with personal protective equipment, walking through storage routines, and learning how to spot alert signs—see fewer accidents. Workers who feel comfortable speaking up when they spot condensation or worn-out barrels make storage safer for everyone.

At the end of the day, taking benzoyl chloride seriously saves both health and money. A few hours spent on upkeep and routine checks always costs less than lost inventory, environmental fines, or a trip to the emergency room.

Understanding the Dangers

Benzoyl chloride doesn’t act like common household waste. It’s a hazardous chemical, irritating to skin, eyes, throat, and lungs, and reacts fiercely with water, releasing hydrochloric acid fumes. Many years ago in a campus lab, I watched someone mishandle a similar compound—one whiff of those harsh fumes, and nobody needed a reminder about safety after that. These qualities place benzoyl chloride squarely in the “handle with care” category. The EPA puts benzoyl chloride on its hazardous waste lists for good reason. Accidental disposal down the drain or in regular trash doesn’t just create corrosion or chemical burns. It can spark fires or build toxic clouds that harm anyone nearby, and the aftermath contaminates soil and water systems.

Rules and Experience

Every local and federal law treats benzoyl chloride as a hazardous waste requiring strict regulation. OSHA and EPA spell out rules with zero ambiguity. Institutions that take safety seriously insist on using sealed, labeled containers made of glass or compatible high-density polyethylene, never metal—nobody wants a leak or a meltdown. In a lab, I’ve seen specialized fume hoods set aside for its transfer, and entire waste stations set up just for halogenated organics like this.

No Room for Shortcuts

Pouring leftover benzoyl chloride down the drain won’t just ruin plumbing. It sends toxic chemicals to treatment plants unequipped for them. Direct release creates acid, and that acid damages pipes and the folks trying to fix or clean them. Burning or evaporating benzoyl chloride isn’t an answer, either—this practice produces phosgene and hydrochloric acid fumes, which put health at risk and break clean air laws.

What Actually Works

Licensed chemical waste disposal companies take center stage in solving this problem. Their workers understand containment, neutralization, and safe transport. Collection happens in solid glass bottles, all labeled with date, quantity, and other specifics. Some industrial users treat benzoyl chloride in closed reactors to break it down—typically neutralizing with a strong base, then quenching the mixture fully under controlled conditions. No one tries this in a home or typical workplace. Colleges and major labs keep a schedule—every week or month—to remove all hazardous waste, including this one.

Prevention and Safer Alternatives

Rethinking use can lower disposal headaches. Sometimes safer compounds, like benzoic acid derivatives, serve the same role in chemical synthesis. Ongoing research from organizations like the National Institute for Occupational Safety and Health (NIOSH) and green chemistry advocates push for substitutes with lower hazards. Upgrading to safer chemicals where possible creates fewer risks and smaller bottles waiting for hazardous waste pickup.

Responsibility Matters

The biggest warning from past accidents stays clear: skipping regulations on chemical disposal creates a legacy of injuries and environmental contamination. No one wants benzoyl chloride mixing into soils or rivers. If your workplace or school still stores forgotten drums from old experiments, it’s important to contact the local hazardous waste service as soon as possible. Their expertise keeps chemicals contained and out of the ecosystem. Proper disposal costs money, but the price of disaster far outweighs savings from any shortcut. Holding ourselves to these high standards isn’t optional—it's the only practical route to protect health and land.

The Hidden Dangers Lurking in Industry

Factories and laboratories across the world use Benzoyl Chloride as a building block in chemical production. You’ll find it behind the scenes in plastics, dyes, pharmaceuticals, and even some pesticides. Despite its common use, not everyone takes seriously how harmful exposure can be on the body. Having worked in an industrial research setting, I’ve witnessed the urgency that follows an accidental spill. Even a few drops in the wrong place cause chaos: alarms blare, people rush for ventilation, and spills need careful cleanup. That doesn’t happen by chance—it’s because Benzoyl Chloride means real danger.

Short-Term Exposure: Immediate Impact on Health

Folks who breathe in Benzoyl Chloride notice its effects quickly. It irritates the nose, throat, and lungs, leading to coughing, shortness of breath, and sometimes a choking feeling. People exposed to high levels may struggle for air or even experience water in the lungs, a life-threatening condition called pulmonary edema. Coming into contact with the skin brings severe burns, and eye exposure holds the risk of permanent vision loss.

Its acrid odor acts as a warning sign but doesn’t guarantee safety. Concentrations that damage the lungs may not smell strong enough to trigger an alarm. This is where the risk multiplies, especially in small businesses or labs without top-of-the-line safety systems.

Long-Term Hazards: Damage You Can’t Always See

Chronic exposure causes its own problems. Repeated contact with this chemical sometimes leads to dermatitis—persistent skin irritation and rashes that never seem to heal. Over months and years, evidence suggests Benzoyl Chloride targets the respiratory system, possibly setting the stage for chronic bronchitis or worsening asthma. Some animal studies have hinted at more serious impacts on internal organs, making sustained, regular exposure concerning for workers.

Community Risks and Environmental Fallout

Benzoyl Chloride doesn’t stay put after it spills. It has a nasty habit of spreading through air and water, and once it hits moisture, it reacts fast to make hydrochloric acid and benzoic acid. Hydrochloric acid especially attacks lungs, metal, and the structure of buildings. This goes beyond just worker health; communities living near chemical plants could face serious hazards from leaks, runaway reactions, or transportation accidents.

Clear Solutions: Practical Actions That Save Lives

The path to safety starts with training. Workers need firsthand instruction on how to handle Benzoyl Chloride and what to do in an emergency. Proper gear—gloves, goggles, and respirators—makes the real difference. Good ventilation and quickly accessible eyewash stations stop an accident from becoming a tragedy.

Company leaders have a responsibility to invest in leak detection and containment. It’s not just about following rules—regular maintenance, real audits of protective gear, and updating emergency plans shape a place where people can work without fearing the next shift. Third-party safety inspections bring a fresh perspective, identifying risks that might slip past tired eyes.

Regulators can step up, too. Requiring clear labeling, regular air monitoring, and tougher reporting rules keeps everyone honest. Community groups nearby need transparent updates about what’s stored in local plants and what’s at stake if something goes wrong.

No Substitute for Respect

Benzoyl Chloride plays a role in the modern world, but it demands respect. Facts and real-world experiences point to a single conclusion: safety isn’t optional. Keeping workers and neighbors safe takes more than rules—it calls for ongoing attention, real investment, and honesty about the risks. That’s how we keep serious harm out of the workplace and the community.

| Names | |

| Preferred IUPAC name | Benzoyl chloride |

| Other names |

Benzenecarbonyl chloride

Benzene carbonyl chloride Benzoic acid chloride |

| Pronunciation | /ˈbɛn.zɔɪl ˈklɔː.raɪd/ |

| Identifiers | |

| CAS Number | 98-88-4 |

| Beilstein Reference | 605412 |

| ChEBI | CHEBI:17608 |

| ChEMBL | CHEMBL14013 |

| ChemSpider | 7697 |

| DrugBank | DB14089 |

| ECHA InfoCard | 100.800.12 |

| EC Number | 204-402-9 |

| Gmelin Reference | Gmelin Reference: 83360 |

| KEGG | C01745 |

| MeSH | D001568 |

| PubChem CID | 7414 |

| RTECS number | CU4375000 |

| UNII | LTK525QM7U |

| UN number | UN1736 |

| Properties | |

| Chemical formula | C7H5ClO |

| Molar mass | 140.57 g/mol |

| Appearance | Colorless to slightly yellow liquid |

| Odor | Pungent |

| Density | 1.21 g/cm³ |

| Solubility in water | Reacts |

| log P | 1.844 |

| Vapor pressure | 1 mmHg (20°C) |

| Acidity (pKa) | 1.8 |

| Basicity (pKb) | pKb ≈ -7 |

| Magnetic susceptibility (χ) | -44.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.553 |

| Viscosity | 1.263 mPa·s (20 °C) |

| Dipole moment | 1.75 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 309.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -165.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -516.7 kJ/mol |

| Pharmacology | |

| ATC code | D10AE01 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06 |

| Pictograms | GHS02, GHS05, GHS06 |

| Signal word | Danger |

| Hazard statements | H302, H314, H317, H332, H335 |

| Precautionary statements | P280, P301+P330+P331, P305+P351+P338, P308+P310, P261, P303+P361+P353, P304+P340, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-2-W |

| Flash point | 72 °C |

| Autoignition temperature | 158°C |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 oral rat 1500 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 441 mg/kg |

| NIOSH | NIOSH: DM4375000 |

| PEL (Permissible) | PEL: 0.2 ppm (OSHA) |

| REL (Recommended) | 35.7 |

| IDLH (Immediate danger) | 200 ppm |

| Related compounds | |

| Related compounds |

Chlorobenzene

Benzyl chloride Benzoic acid Benzyl alcohol Benzonitrile |