Chloroform: The Legacy and Ongoing Challenges of a Notorious Compound

Historical Development

Chloroform arrived in the limelight in the 19th century, a discovery claimed by several chemists almost simultaneously. In the early days, doctors hailed it as a game-changing anesthetic, and it soon took its place in hospitals and operating rooms. Stories from old medical journals show chloroform’s dual image: life-saving for some, deadly for others. By the early 1900s, tragedies involving improper dosage and mysterious deaths led surgeons and scientists to reconsider its widespread use. Later on, regulations tightened up, nudging the compound away from anesthesiology but not out of the conversation entirely. Forgetting how drug development moved through trial by error, just like it did with chloroform, would mean missing a major lesson from medical history.

Product Overview

Chloroform sits in labs and factories as a clear, colorless liquid with a distinct odor. If a scientist needs a solvent for organic reactions or an extractor for plant materials, chloroform probably gets mentioned. It doesn’t dissolve in water worth much, preferring to hang with non-polar compounds—this single trait defines much of its professional utility. In practice, chemists learn to appreciate chloroform’s ability to blend with certain hydrocarbons and alcohols but keep it well away from heat and flame. Industries, particularly pharmaceuticals and agrochemicals, mix it with care to achieve results ordinary solvents can’t deliver.

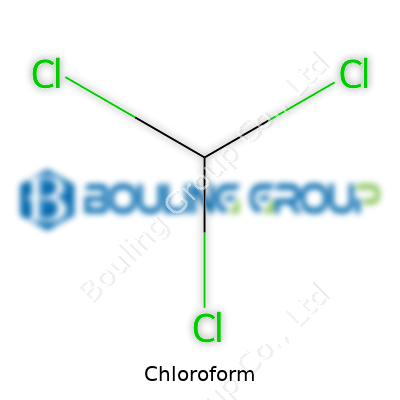

Physical & Chemical Properties

Chloroform’s boiling point—right around 61 degrees Celsius—means it evaporates faster than water but doesn’t disappear in a flash. The liquid weighs more than water, and you can see it form a separate layer if poured gently. As a halogenated hydrocarbon, it resists mixing with water, but latches onto organic solutes with gusto. Chloroform holds a slight sweetness in its scent, but exposure can bring dizziness or worse. Sunlight and air slowly turn it to phosgene, a far more hazardous byproduct. In the lab, this reality prompts staff to work with protected storage and dark bottles.

Technical Specifications & Labeling

Reputable suppliers break down chloroform’s specs with detail: purity above 99% for analytical use stands as a non-negotiable, while industrial batches sometimes show traces of ethanol or methanol to stabilize the product. Labels warn of carcinogenic potential and flag it as a hazardous material; you’ll see UN numbers, proper shipping names, and hazard pictograms on every drum or bottle. Technical sheets spell out shelf life and give storage recommendations—cool, dark rooms with controlled ventilation. International agreements, such as those from the Globally Harmonized System (GHS), make sure anybody handling chloroform knows what’s inside those containers.

Preparation Method

Chloroform comes to life through the reaction between chlorine and methyl alcohol or acetone. On an industrial scale, the preparation starts when chlorine gas drips into a tank of boiling ethanol or acetone. The reaction produces trichloromethane—what we call chloroform—plus a mess of side-products. Manufacturers keep tight rein over temperature, timing, and feed ratios. Impurities can backfire in downstream chemical reactions. Once formed, the crude product passes through distillation columns to strip away undesirable byproducts and meet purity targets. Raw skill counts here as much as modern controls; operators juggle conditions to maximize yield and avoid phosgene and other toxic offshoots.

Chemical Reactions & Modifications

Chemists see chloroform as both a tool and a stepping stone. The compound’s carbon-hydrogen bond remains notably reactive. Strong bases or intense heat crack it open, sometimes liberating dichlorocarbene—a highly useful intermediate in synthetic chemistry. Chloroform acts as a solvent for a stack of organic reactions but can itself get modified in halogenation or substitution procedures. The ability to take chloroform and coax it into new compounds makes it a foundational building block in many pharmaceuticals and dyes. In some classic protocols, such as the preparation of isocyanides or certain pharmaceuticals, handling chloroform remains a core step.

Synonyms & Product Names

Depending on the task or the geography, chloroform hides behind a bevy of alternative names: trichloromethane, methyl trichloride, and TCM appear in chemical catalogs and regulatory lists. In trade, it shows up as “Chloroform, technical grade” or just “Lab solvent—trichloromethane.” This sheer variety in nomenclature can trip up even experienced professionals, especially when ordering supplies or filing paperwork for transport across borders. Staying sharp about synonyms often means the difference between a compliant shipment and a flagged customs form.

Safety & Operational Standards

Forget the old movies with ether-soaked rags. These days, strict rules govern every milliliter of chloroform. Engineering controls—chemical hoods, vapor sensors—stand as the first line of defense. Personal protective equipment includes gloves, goggles, and solvent-resistant aprons. Storage must happen away from sunlight and oxidizers, with spill kits never far away. Emergency showers and eye wash stations stay prepped just in case of accidental exposure. Most workplace safety standards trace back to agencies like OSHA, who recommend limits for airborne chloroform and advise medical surveillance for staff with regular exposure. Mixing or heating chloroform can’t happen without considering the risk of phosgene formation, which takes the threat from severe to potentially fatal.

Application Area

Pharmaceutical manufacturing still puts chloroform to work as a reaction medium, thanks to its unique solvent properties. Forensics labs extract drugs and toxins from biological tissues using chloroform. Chemical analysts rely on it as a phase in liquid-liquid extraction, separating compounds cleanly for identification. Chloroform gives up its secrets in agriculture too, where it extracts pesticides from soil samples or helps researchers track residual chemicals through the food chain. Industrial-scale synthesis of PTFE (better known as Teflon) rests on the availability of chloroform as a feedstock, while rare but important uses still pop up in synthesizing dyes and fragrances.

Research & Development

Although chloroform’s prominence waned in medicine, research persists around safer use and environmental impacts. New detection technologies now flag trace amounts in air and water with remarkable sensitivity. Investigators look for greener ways to produce and reclaim chloroform, aiming to cut emissions and avoid persistent organic pollutants. Ideas from green chemistry—like catalytic routes or photo-assisted syntheses—get tested at the bench scale, with an eye on tighter regulation and shrinking profit margins. In-house R&D for chemical companies considers not just performance but also downstream waste and regulatory hurdles. Ongoing studies focus on how processing conditions influence phosgene byproducts and how to trap them before they pose trouble.

Toxicity Research

Toxicologists approach chloroform with respect and wariness. Research over decades shows the compound damages the liver and kidneys, with chronic exposure increasing risks of certain cancers. Animal studies support a cautious approach in workplaces and neighborhoods near industrial sites. Inhalation remains the primary worry, although the skin can absorb liquid chloroform, and ingestion—accidental or malicious—brings severe consequences. Regulatory agencies such as the EPA and IARC classify chloroform as a probable human carcinogen based on animal data and workplace reports. Advances in toxicity screening and genomics tie exposure levels to health outcomes more clearly than ever before, helping enforce tougher workplace and environmental standards.

Future Prospects

Legislation pressures manufacturers to find alternatives with less toxicity and lower environmental persistence. The rise of green chemistry inspires new synthetic techniques that reduce reliance on traditional solvents, including chloroform. Some areas, like synthetic organic research and extraction methods, continue to use chloroform because few substitutes match its unique combination of properties. That said, demands for safer chemicals—rooted in both regulatory and public health pressures—drive research into effective replacements. Emerging technologies in waste treatment and solvent recycling offer hope, aiming to keep residual chloroform out of water, soil, and air. Scientists, engineers, and policymakers follow this compound’s journey closely, balancing legacy uses against modern safety and sustainability demands, always weighing risks with every new study and batch.

The Many Faces of Chloroform

Chloroform is a word most folks recognize from crime novels and old movies. In those stories, it pops up as a mysterious liquid, always on a rag, always knocking someone out in seconds. That image lingers in pop culture, but there’s a real side to chloroform too—a chemical that shaped medicine, industry, and even my own memories from the college chemistry lab.

Hospitals, Research, and Industry

Doctors don’t use chloroform for anesthesia anymore. Back in the 1800s, it offered a shot at painless surgery. Queen Victoria used it for childbirth in 1853. At the time, pain relief counted as a breakthrough, yet chloroform had its problems. People died during operations because the liver struggles to break it down, and it can cause the heart to stop. Today, there are safer, more predictable options.

Now, researchers keep chloroform on the shelf for its ability to dissolve stubborn compounds. In biochemistry, one common job involves separating molecules, pulling DNA or RNA out of cells. Lab technicians combine chloroform with phenol and alcohol. This mixture turns a jumble of cell parts into separate layers that hold protein, DNA, and other bits in neat bands. This isn’t the glamorous side of science, but it’s essential work, helping unlock secrets in genetics.

Manufacturing and Cleaning Up

Factories use chloroform to make refrigerants, like HCFC-22, and also to create Teflon. The plastics, solvents, and dyes that fill hardware stores often have a backstory involving chloroform. If you know anyone in manufacturing, you’ve probably heard about the long list of chemicals workers deal with daily, and chloroform often ranks among them.

Environmental specialists notice chloroform for another reason—it turns up as a common pollutant. Older water treatment plants, or those that use lots of chlorine, sometimes allow chloroform to form as a by-product. Studies from the United States Environmental Protection Agency show that people mostly encounter chloroform by inhaling it in shower steam or drinking tap water. Most municipal water systems test and keep levels low, but not all countries keep up with these guidelines. For communities near chemical plants, the risk goes up.

Straight Talk on Health and Safety

Breathing chloroform can cause headaches, dizziness, and over time, harm the liver and kidneys. In high doses, it can knock someone out or cause death, which explains why regulations keep it tightly controlled. In one summer class, my chemistry professor drilled this home: never work with chloroform outside the fume hood. Several classmates felt woozy after a careless spill. Those lessons stay with you.

The National Institute for Occupational Safety and Health warns about chronic exposure. On the job or in the lab, it’s safety goggles, gloves, and good ventilation, no exceptions. For most people, risks stay low as long as exposure stays low, but the stories of factory workers in earlier decades are a reminder not to take chances.

Looking for Better Solutions

Today, researchers search for greener, safer alternatives. Companies develop new solvents that do the same jobs without lingering toxins. Clean chemistry matters not only for the workers but for communities around chemical plants and water supplies. Good regulation, safer substitutes, and a strong dose of common sense do more to protect people than anything you see in an old detective story.

A Chemical with a Dark Past

Chloroform might look like another clear liquid in a bottle, but its history and effects raise some loud alarms. Back in high school chemistry labs and old detective stories, it seemed almost harmless—a little knock-out fume waving through the air. Those images miss the dangers. I once saw a classmate splash some on his glove, thinking it would just evaporate. Fifteen minutes later, the room reeked, he felt dizzy, and the teacher scrambled to open every window.

Why Chloroform Is Risky

Chloroform passes through the body in unpredictable ways. It soaks in through the skin, seeps into the lungs, and ends up in the bloodstream before you know it. The feeling of sleepiness isn’t just drowsiness—it’s the nervous system shutting down. Long-term contact can trash your liver and kidneys. The U.S. Occupational Safety and Health Administration calls for strict limits on workplace exposure for a reason.

Chloroform’s old role as an anesthetic ended for good reason. People stopped using it in hospitals after too many didn’t wake up. The World Health Organization has flagged it as a possible human carcinogen. Small studies point to connections between chloroform and certain cancers, though pinning down the risk at low levels can take decades.

Unseen Hazards in Everyday Life

Chloroform sometimes forms in tap water during disinfection, especially where water supplies use chlorine. Showers, swimming pools, even a hot bath can deliver tiny doses if the water supply carries those byproducts. In most cities, concentrations stay well below dangerous levels, but water authorities still monitor and make changes when the numbers climb.

DIY fans and amateur chemists sometimes ask in online forums about using chloroform for cleaning or extraction. They risk headaches, organ damage, and even fires. Breathing the fumes makes you unsteady, even before trace poisoning sets in. One mistake with an open acetone bottle or a spark, and the fumes catch fire. Regular gloves from the hardware store don’t stop chloroform either—it soaks straight through.

Better Routes for Science and Home

Strong research labs run fume hoods, specialized gloves, splash goggles, and emergency showers. Home kitchens and garages never come close to that level of safety. Chemical suppliers demand certifications because the risks are real. I remember visiting a university lab; I noticed a full binder of accident reports dating back decades—chloroform showed up too often. Outside trained hands, it doesn't belong in homes.

If someone truly needs a substance with that level of toxicity, odds are the job can be done by something milder. For cleaning, even basic soap and vinegar work better for most stains and never send people to the hospital. In labs, modern solvents often do the same work with much less risk. Teaching moments should focus on safety, not shortcuts. The cost of a medical emergency far outweighs the price of any solvent.

Hard Experience Beats Cautionary Labels

People trust labels and quick tips too much. Experience reminds me these warnings show up because others paid the price. Chloroform isn’t just another liquid on the shelf or a throwaway line in old novels. Respect for it doesn’t come from fear, but from knowing what happens to people who treated it like just another bottle. For anyone outside a real lab, the safest way to handle chloroform is not to touch it at all.

Understanding Chloroform and Its Purpose

Chloroform pops up in conversation sometimes, usually thanks to old movies. It’s a chemical with a long history, once used as an anesthetic in surgeries. People have dreams or concerns about its use for sleep or pranks, but not enough realize its risks and the laws around it.

The Dangers That Can’t Be Ignored

Chloroform carries big health risks. Breathing in chloroform can knock someone unconscious, but the line between that and stopping their breathing isn’t wide. Inhaling too much can harm the heart and liver. I remember learning in a college chemistry class that doctors eventually abandoned it for anesthesia because the side effects outweighed the benefits. Thousands died from complications before safer options arrived. Exposure, especially in a home or unsupervised setting, can land a person in the hospital—or worse.

Regulations don’t exist for show. The US Environmental Protection Agency lists chloroform as a probable human carcinogen. Labs store it with all kinds of red tape. Nobody wants to see people suffer from reckless use or mishaps tied to something as serious as this.

Buying Chloroform — Legality and Access

It’s not as easy as shopping for cough syrup. Chloroform is a controlled substance. In the United States, you’ll need a legitimate business, lab certification, and valid reasons—research, genuine chemistry work, or medical device manufacture. Retail stores and typical online platforms steer clear. The same pattern plays out across Europe, Canada, and many other places.

When requests to buy show up online, vendors usually turn those buyers away or report suspicious activity. Some sketchy corners of the internet fake promises, sell scams, or worse, leave buyers with toxic substitutes. People sometimes think they can make their own, only to risk fire or explosion. There’s enough documentation of ER visits and legal trouble for those who try.

Safer Alternatives and the Path Forward

People who want to obtain chloroform should start by asking what they need it for. Educational demonstrations or science experiments at home have alternatives that don’t endanger anyone’s health. Chemists recommend other solvents for many legitimate uses. Good instructors guide students toward safety and explain the real-life costs of using dangerous substances.

Public awareness changes the game. On TV, chloroform looks like a fast-acting solution with few consequences. Science tells a different story. Honest discussions about chemicals keep kids and adults out of harm’s way. Families, teachers, and young researchers benefit from resources that share facts openly. If someone hears chatter about buying chloroform, they should point toward guidance instead of secrecy.

Real E-E-A-T—experience, expertise, authority, and trust—comes from sticking to the facts and thinking about long-term outcomes. Chasing shortcuts, especially with hazardous chemicals, brings headaches for everyone involved. Society does better when safety stays at the center of any conversation about dangerous substances.

How Chloroform Creeps Into Daily Life

Most people think of chloroform as something pulled from old detective stories or medical dramas from decades back, but it’s not just a thing of the past. Chloroform, once popular as an anesthetic, still pops up in laboratories, some industrial cleaning processes, and water treatment plants. Even some tap water has trace amounts formed as a byproduct.

Short-Term Dangers: Not Just Fainting

People often joke about chloroform making you pass out, but reality is far rougher. Even breathing in a bit too much doesn’t just lead to a quick blackout. Chloroform can irritate eyes, nose, and throat, and it often makes people feel dizzy or nauseous. The stuff goes straight to your nervous system. Enough exposure can drop your blood pressure so fast you risk heart problems. Touching it won’t save you, either—skin exposure can cause rashes, burns, or a strange tingling. In my high school chemistry class, our teacher insisted on gloves and tight lids. Nobody complained, especially after one student landed in the nurse’s office from inhaling too much during an experiment.

Big Risks With Chronic Exposure

The longer you’re around chloroform, the more brutal it gets. It chips away at your liver and kidneys, sometimes without you realizing until the damage is already piled on. Studies pulled from the National Institute for Occupational Safety and Health—trusted by medical professionals—show repeated low-level exposure can spark organ failure, mostly liver or kidney. Even the International Agency for Research on Cancer calls it a possible carcinogen for humans. Tumor risk grows with long exposure. Not many people realize how sneaky this chemical is; those working at water treatment plants or in labs need regular blood checks just to keep ahead of problems.

Neighborhoods Most at Risk

Communities near manufacturing plants or busy labs—especially in older industrial towns—run a bigger risk. Drinking water might hold tiny chloroform traces, and homes close to chemical dumps sometimes end up with higher air levels. Safe water standards help, but families should never have to worry about chemicals floating in from the next street over. Growing up near rail yards, I got used to bad smells, but few in my neighborhood realized the risk wasn’t just to our noses. Testing and transparency matter; people need to know what’s in their air and water.

Solutions That Actually Help

It’s easy to throw up hands and declare chemicals unavoidable, but a few straight-forward changes actually make a difference. Proper ventilation, personal protective gear, and good training go a long way in labs or factories. Home water filters marked as “VOC-reducing” drop chloroform levels, something I recommend to anyone living near known industrial dumping sites. For workers, regular checkups catch problems before they spiral. Companies that invest in safer alternatives and routine monitoring keep their employees and neighbors safer.

No One Gets a Free Pass

Chloroform can’t just be shrugged away as someone else’s problem. Health depends on awareness, action, and demanding accountability from both industry and public officials. Talk to neighbors, push for stronger regulations, and insist on thorough testing. Nobody should wait for the next health scare to care about what seeps into the air or water.

Managing a Powerful Chemical Behind Locked Doors

Chloroform is all over the history books, but in today’s world, most people only spot it on chemistry labels or in the pages of mystery novels. In a functioning lab, this compound brings real risks. Ask any chemist about its hazards, and you’ll get long stories about spills, fumes, and locked cabinet keys. An overlooked bottle can ruin an entire project, throw a health department into a frenzy, or worse, cause a tragedy disguised as a minor incident.

Storage Rules: Don’t Treat It Like Just Another Solvent

Chloroform evaporates easily and turns toxic in the blink of an eye. It reacts with air and light, building up phosgene — a chemical weapon from World War I. Anyone familiar with its sharp odor realizes you need planful storage from the start. I learned early that a brown glass bottle won’t cut corners, even with a label. Genuine safety puts chloroform inside a dark, sealed container, clearly marked, and always tucked away in a flammable chemicals cabinet far from any heat sources.

Refrigeration slows down its decomposition. Still, proper ventilation remains non-negotiable. Many labs use explosion-proof refrigerators just for volatile solvents like this. Sharing shelves with acids, bases, or oxidizers invites disaster. I’ve seen the bill for a single, careless storage mix-up: emergency cleanups, hazardous waste pickup fees, all while staff are left worrying about their next health checkup.

Disposal: The Part Nobody Wants but Everyone Must Respect

Rinsing chloroform down a sink or tossing it in the regular trash seems unthinkable to most scientists, but take a stroll through chemical waste records and you’ll find plenty of horror stories. Instead, responsible workplaces create a tight waste stream. Any old or spent chloroform goes into proper, chemical-resistant waste containers. These containers never just sit in the corner; they get labeled with date, contents, and hazards in clear, permanent ink.

Disposal only works when the right licensed hazardous waste contractor handles the material. Burning, burying, or illegal dumping only fuel public health and environmental scandals. Exposure can taint water tables for years and release cancer-causing fumes into the air.

Building Good Habits & Clear Protocols

Many problems start with confusion. New team members sometimes struggle with chemical hygiene rules, even after hours of training videos. Real knowledge sticks when leaders reinforce these steps every day and keep protocols visible on the wall above storage cabinets. I’ve watched accidents drop to zero when everyone knows the process and feels empowered to speak up after spotting unsafe storage or outdated bottles.

Safety audits—frequent and unannounced—work better than long manuals stuffed away on a shelf. A shared culture where nobody skips steps helps every lab tech, student, or maintenance worker go home healthy. Community colleges and small businesses sometimes lack the support or resources of big companies, but everyone can partner with local disposal services, keep unused inventories low, and update training every time the rules change.

Growing Responsibility Beyond the Lab

Ongoing education, frequent review of chemical lists, and access to the right equipment drive down risks from chloroform. Fewer shortcuts, more oversight, and real personal accountability — these efforts protect not just the people inside the lab, but everyone whose water, air, or soil touches that site generations later. Responsible labs aren’t just following the law. They are looking out for each other.

| Names | |

| Preferred IUPAC name | Trichloromethane |

| Other names |

Trichloromethane

Methane, trichloro- Formyl trichloride Methyl trichloride |

| Pronunciation | /ˈklɔːr.ə.fɔːrm/ |

| Identifiers | |

| CAS Number | 67-66-3 |

| Beilstein Reference | 6352 |

| ChEBI | CHEBI:35255 |

| ChEMBL | CHEMBL1757 |

| ChemSpider | 541 |

| DrugBank | DB01505 |

| ECHA InfoCard | 100.001.022 |

| EC Number | 200-663-8 |

| Gmelin Reference | 1363 |

| KEGG | C00208 |

| MeSH | D002749 |

| PubChem CID | 6212 |

| RTECS number | FQ9625000 |

| UNII | LC8V8T94ZB |

| UN number | UN1888 |

| Properties | |

| Chemical formula | CHCl3 |

| Molar mass | 119.38 g/mol |

| Appearance | Colorless liquid with a characteristic ethereal odor. |

| Odor | Sweet, ethereal |

| Density | 1.48 g/cm³ |

| Solubility in water | 8.09 g/L (20 °C) |

| log P | 1.97 |

| Vapor pressure | 159 mmHg (20°C) |

| Acidity (pKa) | 15.7 |

| Basicity (pKb) | 15.7 |

| Magnetic susceptibility (χ) | −32.5×10⁻⁶ |

| Refractive index (nD) | 1.445 |

| Viscosity | 0.563 mPa·s (20°C) |

| Dipole moment | 1.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 155.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −103.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –524.4 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | N01AB02 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and serious eye irritation, may cause cancer, suspected of damaging fertility or the unborn child, causes damage to organs through prolonged or repeated exposure, may cause drowsiness or dizziness, toxic to aquatic life. |

| GHS labelling | GHS02, GHS06, GHS08 |

| Pictograms | GHS06,GHS08 |

| Signal word | Danger |

| Hazard statements | H302, H315, H319, H336, H351, H361d, H372, H412 |

| Precautionary statements | Precautionary statements of Chloroform: "P201, P202, P261, P264, P271, P280, P301+P310, P303+P361+P353, P304+P340, P305+P351+P338, P308+P313, P312, P330, P337+P313, P405, P403+P233, P501 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Autoignition temperature | 982°F (528°C) |

| Explosive limits | Explosive limits: 15.0–17.0% |

| Lethal dose or concentration | LD50 oral rat 695 mg/kg |

| LD50 (median dose) | LD50 (median dose): 695 mg/kg (oral, rat) |

| NIOSH | NT1225000 |

| PEL (Permissible) | 10 ppm |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Bromoform

Fluoroform Iodoform Methanol Dichloromethane Carbon tetrachloride |