Melamine: Exploring Past, Present and Future

Historical Development

Melamine emerged from the chemical industry in the 19th century, a time marked by exploration of new synthetic routes and substitute materials for daily living. Chemists stumbled across melamine by treating urea with heat, igniting a chain of innovation that would help shape a wide variety of durable goods. After World War II, the demand for tough, affordable plastics grew. Melamine-formaldehyde resin hit the market, bringing the now-iconic melamine tableware into homes, cafeterias, and diners. As demand found new heights, producers around the globe refined the process, aiming for higher purity and fewer impurities that could cause trouble in finished products. In the 21st century, this material’s reputation faced a major test during food contamination scandals, which set off a wave of stricter oversight and new research into safer applications. Spotlights on these events forced suppliers and regulators to draw clearer lines on quality and usage standards.

Product Overview

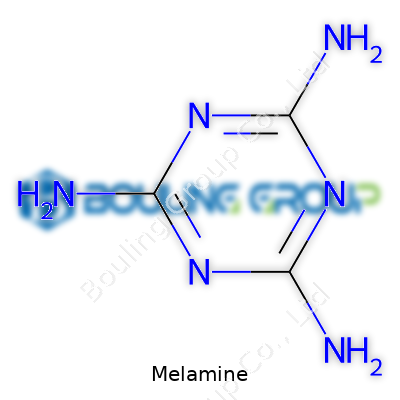

Look around any dinner table from the 1960s forward, and odds are good there’s melamine there somewhere—dishware, countertops, kitchen gadgets. Melamine’s strengths come from its structure: triazine rings packed with nitrogen atoms, making it tough and resistant to heat. Kettles, panels, and flooring all benefit from its resilience and ability to hold shape. It also finds its way into coatings, adhesives, and flame-retardant systems. Industrial uses haven’t slowed down, as commercial flooring, automotive interiors, and decorative laminates rely on melamine’s unique mix of durability and versatility. Easy shaping and smooth finishes help products shine, but the market learned hard lessons about unintended uses, especially in the context of food safety. Each phase of melamine’s spread into products revealed fresh challenges—especially keeping it out of places it clearly doesn’t belong, like dairy or grain supply chains.

Physical & Chemical Properties

Melamine comes across as a white crystalline powder at room temperature. It holds solid at high temperatures, not breaking down easily—making it attractive for kitchenware destined for tough environments. The nitrogen content, topping 66%, delivers both strength and fire resistance. Water won’t dissolve it, but it mixes freely with formaldehyde during the resin-making process. Over many years, tool-makers and chemists found that melamine’s high melting point (above 340°C) lets it handle baking, boiling, or high-temperature pressing without turning brittle. Sturdy hydrogen bonds between molecules explain why finished products keep their shape under daily pounding. Handling melamine in powdered form can create dust, so industries tuned their production and packaging to cut down on workplace exposure. Its chemical backbone means melamine seldom reacts with household chemicals—another reason it pops up so often in surfaces that get cleaned regularly or exposed to food acids.

Technical Specifications & Labeling

Product quality hinges on meeting technical benchmarks. For food contact materials, melamine resin has to hit strict purity marks—99.8% or higher—and pass leach testing to confirm tiny fractions migrate into food, if at all. Manufacturing certificates often list moisture content (under 0.1%), ash content, and pH range to avoid off-tastes or failures in lamination. Labels usually signal compliance with standards from agencies like the European Food Safety Authority (EFSA), the U.S. Food and Drug Administration (FDA), or China’s National Food Safety Standard system. Full traceability and batch analysis reports tackle the lessons learned from past health incidents. Factories stamp goods with lot numbers, destinations, and testing dates. Some big players go further—tracking the urea source, monitoring process temperatures, and keeping sample libraries in case of future complaints. Robust labeling plays a crucial role in reassuring buyers and regulators that shortcuts haven’t crept in—especially when final products end up in places as sensitive as hospital kitchens or daycare centers.

Preparation Method

The backbone of melamine production still revolves around heating urea under pressure. During the thermal decomposition of urea, ammonia leaves the reaction and melamine forms through condensation. Factories fine-tune the process to curb impurities, limit side-products, and recover unreacted ammonia. Modern reactors run at high pressures (typically 8–20 atm) and at temperatures ranging from 300°C to 400°C. Any slip-up in temperature or pressure can lead to cyanuric acid byproducts, which spell headaches during product testing. Equipment downstream captures volatile gases and purifies the solid material before milling and packaging. Several large-scale plants operate on closed-loop systems to recapture ammonia, trimming costs and environmental footprint. Investment in catalyst development and process automation has paid off, driving down energy usage per ton and making melamine one of the more eco-conscious outputs from the chemical sector by volume. As with most petrochemical-adjacent industries, cleanup and emissions control require constant vigilance.

Chemical Reactions & Modifications

Melamine reacts best as a building block, thanks to available amine groups. The blockbuster commercial application—the reaction with formaldehyde—produces melamine-formaldehyde resin, a compound that crosslinks strongly when cured. These crosslinks underpin the hardness of molded dinnerware, toughened panels, and scratch-proof cabinetry. Other popular modifications include combining with phosphates for fire-retardant fillers or sulfated agents for specialty polymers. Researchers have coaxed more complex chemistries by adding reactive dyes, UV stabilizers, or anti-static agents, stretching melamine’s reach beyond just structural use. Some new projects in electronics harness its insulation properties in circuit board substrates. In bulk manufacturing, adding modifiers into the mix can mean juggling reaction time, curing temperature, or even particle size, tuning material performance for specific applications. The chemistry has never stopped evolving—industry keeps looking for partners and modifiers that push melamine into the next big field, especially where tougher safety or durability standards are needed.

Synonyms & Product Names

Shifting through catalogs and inventories, melamine appears under several tags. The official IUPAC name is 1,3,5-triazine-2,4,6-triamine, but few outside textbooks use it. Trade names like Cyanuramide and Triaminotriazine pop up in technical literature, especially when buyers hunt for substitutes or specialty batches. In Europe and parts of Asia, standard product names like "melamine resin" signal whether it’s raw powder, prepolymerized, or blended with toughening fillers. Major resin producers often sell branded blends for high-stress architectural laminates or adhesive use, but savvy buyers pay closer attention to certificates of analysis than to catchy brand titles.

Safety & Operational Standards

Winding through a melamine production line or molding plant, safety culture touches every step. Inhalable dust ranked as a top concern for decades, leading to upgrades in ventilation, personal protective equipment (PPE), and automated handling systems. Occupational exposure limits—set by agencies such as OSHA or ECHA—show how much the industry learned from early accidents. Proper storage cuts risks of decomposition or spillage, as does strict temperature control during handling. On the consumer front, regulatory agencies set allowable migration levels of melamine from finished goods, especially foodware. For example, the European Union capped melamine migration into food at 2.5 mg/kg, driving tighter batch controls. Training operators to spot defects, check pressure readings, and track batch lots lowers risk and halts compromised product before it reaches users. During logistics and storage, keeping barrels or sacks out of damp and away from acids prevents slow degradation and potential loss of strength. Mock recall drills, supplier audits, and customer hotlines aim to catch trouble early, passing on hard-earned lessons from past scandals.

Application Area

Melamine’s utility stretches from the dinner table to skyscrapers. Everyday folks think of colorful plates, mugs, mixing bowls—the kitchen staple for decades. Behind the scenes, architects specify melamine-faced chipboard for office desks, closets, wall panels, and flooring, owing to its easy cleaning and scuff resistance. Industrial sites count on melamine as a flame retardant for wire coatings, insulating foams, and even in automotive roof liners. Paper companies treat banknote stock, playing cards, and high-gloss posters with melamine solutions for a crisp, durable finish. Chemical plants blend it into paints, adhesives, and thermosetting composites. As construction trends emerge, designers push for lighter, more sustainable building materials; here, melamine shows up as a critical binder in particleboards and other engineered wood products. Sports venues, hospitals, airports—everywhere hard-wearing, safe surfaces matter—absorb a steady flow of melamine-based goods. Research teams in electronics turn to new melamine derivatives to build stable, heat-resistant materials for high-performance device assemblies. Even water treatment specialists experiment with melamine-infused filters or membranes to boost longevity under tough conditions.

Research & Development

The ceaseless march of product R&D never leaves melamine behind. Academic labs and industrial test kitchens drive new uses: blending with bioplastics, lowering formaldehyde content, and scoping out replacement curing agents. Digital modeling and material science open new doors, testing how modifications at the molecular level impact performance under real-world abuse. As regulations evolve, R&D focuses on lowering toxicological risks and boosting biodegradability. Projects tracking leaching, recycling potential, and safer processing keep the innovation pipeline busy. Real progress shows in smart composite panels or self-healing coatings for high-traffic spaces, where melamine’s properties pair with new tech. Sustainable sourcing and cradle-to-cradle recycling win attention from large furniture makers and government buyers, especially in Europe. Universities pitch new blends, micro-structured surfaces, or water-resistant grades for demanding infrastructure in flood-prone regions or bustling cities. More recently, startups dangle biobased cross-linkers, aiming for higher safety margins with the same toughness that put melamine on the map.

Toxicity Research

The sharpest public health focus on melamine hit after food adulteration incidents, exposing how small amounts could cause kidney problems, especially in children. Research drew a clear line between safe, indirect contact (finished, well-cured tableware) and illegal direct adulteration (spiking milk or gluten to fake protein levels). Animal studies found repeated, high-dose exposure triggered urinary stones or renal failure. Regulators set strict migration and exposure limits, clamping down on poorly-made imports and fake food ingredients. Follow-up studies looked for links to reproductive effects or cancer, prompting new rounds of risk assessment. Factories and certification labs set regular leaching tests—hot acidic liquids in contact with melamine-surfaced bowls or cups—for every new product batch leaving the line. Health organizations urge parents to avoid microwaving acidic foods in melamine dishes—simple steps that slash potential risks. Ongoing environmental studies check for breakdown products in groundwater or soil, though most agree well-made melamine products hold hazards only for those who cut corners or flout standards.

Future Prospects

Melamine stands at a crossroads where safety, sustainability, and high-performance demands intersect. Tightening rules on food safety and workplace exposure drive steady investment in cleaner chemistry, better dust control, and sharper quality checks. Green chemistry encourages development of bio-based feedstocks, biodegradable composites, and lower-emission resins paired with melamine’s core performance. Building codes and workplace standards lean into demand for fire-retardant, long-lived materials—exactly where melamine outshines cheaper rivals. Digital manufacturing and automation streamline small-batch specialty material runs, allowing rapid tweaks for new uses in electronics, filtration, or even medicine. Global trade keeps moving, so traceability and instant batch recall methods take center stage. Safety-conscious consumers push for transparency: data on food contact, leaching, and end-of-life handling. Melamine’s next era likely won't hinge on raw toughness, but on seamless pairing with environmental stewardship and airtight safety systems. Companies unable to adapt fall behind as regulations clamp down and buyers demand both performance and peace of mind—creating fresh room for innovators to rewrite melamine’s story.

Where Melamine Shows Up

Melamine stands out as a white, powdery compound made up of nitrogen, carbon, and hydrogen. Most people come across melamine without realizing it, especially in kitchens and offices. Manufacturers mix melamine with formaldehyde to make resin, which hardens into materials found in countertops, plates, bowls, and many household goods. Cafeteria trays, children's cups, and even the funky-colored dinnerware at so many picnics start out in a factory where melamine and formaldehyde resin get molded under heat and pressure. Furniture makers use particleboard bonded with melamine resin, creating those affordable cabinets and desks in so many homes.

Why Melamine Matters

Melamine doesn’t break down easily. That’s good for durability; everyday dishes don't chip or scratch as quickly. It can handle hot food, frequent washing, and drops to the floor that would shatter glass or ceramic. Hospitals and schools rely on melamine dishware to cut down on costs and accidents. As families search for budget options, melamine pops up in stores because it stays bright, doesn’t weigh much, and costs less than porcelain or glass.

Still, scratch the surface and risks begin to show. Melamine became a household word after scandals in China where unscrupulous suppliers added it to milk and infant formula to fake higher protein levels. Melamine contains lots of nitrogen, and standard protein tests measure nitrogen. Ingesting melamine can lead to kidney stones and damage, especially in children. Over 50,000 infants fell ill in 2008 as a result. It’s not just a distant problem. Reports also reached the United States, raising questions about imported foods and supply chain trust.

Beyond outright cheating, concerns circle back to the dinner table. Using melamine dishware for hot soups or microwaving leftovers can release small amounts of the chemical into food. Scientific studies tracked this, showing that acidic or hot foods can speed up the leaching process. The U.S. Food and Drug Administration found that tiny levels from regular dishware don’t seem to cause harm, but parents and cooks need to know—melamine plates shouldn’t go in the microwave. Stick to ceramic or glass for heating.

What Can We Do About Melamine Safety?

People have a right to know what they’re buying and placing on their tables. Labels in stores could do more than just mention “melamine”—they could stress the limitations on safe use. Schools and childcare centers should replace scratched or worn bowls and cups, because the more scratched they get, the more likely melamine slips into food. Most importantly, stricter supply chain oversight blocks contaminated ingredients from ever reaching milk powder, baking mixes, or pet food.

Manufacturers need incentive to innovate. Safe alternatives to melamine resin exist, though usually at a higher cost. Governments can set better standards for testing—checking food products, not just for known toxins, but for substances like melamine that get misused for profit. Consumers play a role here too. Reading labels, tossing damaged dishware, and speaking up for food safety at the store all keep the issue in the public eye.

Melamine makes modern life easier and more affordable, but cuts corners when misused. A little awareness and straightforward information go a long way in keeping kitchens—and families—healthier.

Understanding Melamine in the Kitchen

Melamine has become a familiar name for anyone who’s browsed through stacks of colorful plates in the local home goods store. Tough, lightweight, dishwasher-safe—what’s not to like? Yet, many people stop in their tracks once they hear about past food safety scares linked to melamine. As someone who prides themselves on grilling with family every summer, I’ve leaned on melamine cups and bowls around lively tables more times than I can count. Still, some real concerns come up when sharp edges like health and safety pierce the friendly image of this kitchenware staple.

How Safe Is Melamine for Food Contact?

No one wants to second guess the safety of their own plates. Food contact rules demand strong science, and groups like the U.S. Food & Drug Administration (FDA) and European Food Safety Authority (EFSA) have set strict standards for melamine. FDA research has shown that, under ordinary use, melamine tableware doesn’t release enough melamine or formaldehyde—a chemical used to make melamine resin—to disrupt human health. The key limit: under 2.5 mg of melamine per kilogram of food. Most kitchenware falls well under that number.

Trouble starts when folks use melamine for things it’s not built to handle. Pouring boiling water or zapping bowls in the microwave bumps up the risk. Studies published in journals like Food and Chemical Toxicology show that high heat or acidic foods (think tomato sauces or lemon curd) coax more melamine off the surface and into your meal. Businesses selling these products have to label them “not microwave safe” for a reason—heated melamine just doesn’t handle high temps the same way glass or ceramic does.

Personal Perspective: Choosing Safer Options

My own kitchen is full of battle-tested dishes, yet I tend to save melamine plates for picnics or snacks. It’s not fearmongering—it’s just caution born from watching news headlines about contaminated milk from China several years back. That scare stemmed from melamine fraud, not tableware. Still, it left many folks doubting the plastic’s reputation.

What the Data Really Tells Us

Plenty of research track melamine’s path through the body. EFSA points to animal studies showing kidney damage when doses creep much higher than anything found with normal dinnerware use. Occasional exposure, especially at low doses, seldom causes trouble for healthy adults. Infants and small kids, yet, have more sensitive kidneys. France’s food safety authority ANSES recommended steering clear of melamine resin cups for hot baby foods.

Scratched plates and worn cups give more reason for pause. With deep grooves or cloudy finishes, plastics break down faster and leach more. Tossing old melamine gear once it’s seen too many dishwasher cycles makes sense—something I’ve done more than once as a parent.

What Can Consumers and Regulators Do?

Relying on clear labeling helps. Dishware manufacturers must spell out if a plate or bowl shouldn’t touch hot liquids or the microwave. When in doubt, grab glass or ceramic for heating food, especially for kids.

Regulators can keep pushing for rigorous limits and random product checks. More consumer outreach—especially warning parents about melamine’s limits in the microwave—would clear up confusion. Keeping both science and lived experience in mind, most folks can keep using melamine safely. Choosing safer habits doesn’t need to turn dinner prep into guesswork.

Everyday Experiences with Melamine

Melamine plates and cups have a spot in just about every home. With their sturdy build and bold designs, they handle daily bumps better than most. Yet, anyone who’s scrubbed at curry stains or wondered why their picnic sets get cloudy has faced the little mysteries of melamine care. It's tempting to treat these as indestructible, but a little extra effort can make them look good for years.

Dishwashing and Temperature Matters

Melamine’s strength comes from a type of resin, which stands up to most shocks but doesn’t react well to high heat. Tossing melamine pieces in the lower rack of a dishwasher exposes them to higher temperatures, and over time, they can warp or lose their finish. I’ve seen old family sets go hazy or the surface peels away. Placing items on the top shelf, away from the heating element, gives much better results. Skipping the sanitize cycle prevents cycle-related cracking. It's a simple tweak that pays off.

Cleaning Up Messes and Stains

I often reach for a soft sponge, not scrubby steel wool or harsh pads, when cleaning up after chili night. Melamine scratches easily, and those tiny grooves collect more stains with every meal. Warm water and mild dish soap handle most of the cleanup. For stubborn marks—think tomato sauce leftovers—a paste of baking soda and water helps. I let it sit a few minutes, then rinse and dry. Avoid chlorine-based bleaches, since those break down the resin, making the surface brittle. In extreme cases, hydrogen peroxide diluted with water can restore brightness without harshness.

Melamine and Microwaves: Not a Good Match

Microwaves warp or crack melamine. Common sense makes a good guide here—if a cup or plate ever feels hot coming out of the microwave, there’s a good chance it’s not supposed to be there. I’ve seen cracks start at the edge after someone heated leftovers directly. Official guidance from health agencies, such as the FDA, confirms melamine should stay out of the microwave. It's not just a cosmetic issue. The resin can break down and leach out. Better to reach for glass or labeled microwave-safe containers for reheating.

Avoiding Direct Contact with Sharp Knives

Family dinners can get lively, but melamine doesn’t handle steak knives or cleavers well. Those cuts—no matter how small—show up as gray streaks or deep scratches. They don’t affect safety right away, but the item gets harder to clean. The best habit is to slice tougher foods on a separate cutting board. Melamine trays and plates keep their good looks longer that way.

Storage and Longevity

Stacking melamine too tightly in cabinets or leaving them in direct sunlight weakens the color and shape. I keep my pieces loosely stacked, allowing enough airflow to prevent trapped moisture. Fading colors suggest it’s time to rotate stock, especially if items live on a sunny windowsill.

Why Proper Care Matters

Safe melamine use lines up with everything I look for—durable, practical kitchen tools that don’t need constant replacing. With smart handling, these products offer long-lasting service, which keeps them out of landfills and supports family health. Caring for melamine means keeping a close eye on surface wear, avoiding unnecessary heat, and washing with care. Simple actions make these everyday favorites last.

Every Kitchen Sees Melamine Dishes

Almost everyone has a stack of those sturdy, brightly colored dishes stuffed in their cabinets. Melamine plates have been a staple at kids’ birthday parties, summer picnics, and busy kitchens for years. The lightweight, nearly shatterproof material makes cleanup easier and keeps dish replacements to a minimum. Some of us grew up with the same set that survived countless drops. Versatile as they seem, melamine dishes spark hot questions about safety, especially around microwaves and dishwashers.

A Closer Look at Melamine

Melamine resin starts as an organic compound blended with formaldehyde, forming a hard plastic. Manufacturers tout the strong material because plates, cups, and utensils rarely chip or snap like pottery or glass. If you handle the occasional barbecue or kids’ meal, melamine saves your nerves.

Most folks notice a “not for microwave use” message stamped on the bottom. There’s a reason for that. Melamine reacts to direct, prolonged heat. The surface gets hot, warps, or even cracks. Worse, at high temperatures, trace amounts of melamine—along with chemicals used during manufacturing—can leach out. The U.S. Food and Drug Administration (FDA) confirms that microwaving melamine increases the risk of these chemicals finding their way into food and beverages, especially with acidic foods like tomato sauce or citrus. Research from the National Institutes of Health backs this up. Tiny, consistent exposures stack up, especially for kids.

Dishwasher Dilemma

Many melamine products say they’re “top rack dishwasher safe.” Real-world experience shows that most of the time, this works just fine. Typical dishwasher cycles do not get as hot as a microwave. Still, after hundreds of washes, older plates might start to fade, or the surface might roughen. That means the outer layer is breaking down, and it’s best to cycle those dishes out of use. The FDA has found no strong evidence that melamine leaches out at dishwasher temperatures in a way that impacts health. You get some wear and tear, nothing more.

If your dishwasher runs scalding cycles or you use extra-hot drying, consider hand washing just to keep melamine in better shape for the long haul.

Smart Solutions and Everyday Choices

People ask if microwaving leftovers on melamine plates once or twice causes problems. Most studies say risk shoots up with repeated, lengthy exposures. Still, why roll the dice over something as basic as reheating? Glass, ceramic, and microwave-safe plastic do a better job and free you from worry.

Picking plates that fit your lifestyle matters, but health sits at the table too. Melamine doesn’t belong in the microwave. Use it in the dishwasher—with care—and toss scratched or faded plates. For those who want safety and the peace of mind that comes with it, reach for glass or ceramic before you nuke your next bowl of soup.

Growing up, I watched melamine plates survive family chaos, camping trips, even backyard barbecues. My mother never dared put them in the microwave, but the dishwasher kept them going strong for ages. That same simple habit still saves headaches today. Ask around, and you’ll likely hear the same advice from chefs, home cooks, and parents: melamine plates belong anywhere but the microwave. They hold up through the dishwasher, but eventually, even the toughest plates run their course.

The Upside of Melamine

Melamine always shows up in my kitchen cupboards. Those lightweight, colorful plates survive rowdy family dinners and rough cycles in the dishwasher without cracking. The main sell here is durability mixed with a clean look. Melamine, a synthetic resin, forms when scientists combine melamine with formaldehyde. The result is a tough plastic that stands up to scratches and stains. For folks raising children or running cafeterias, those features beat regular ceramics or glass every time. You drop a melamine bowl, it usually bounces.

Melamine’s heat resistance lets it handle hot foods, though not for cooking or microwaving. Coffee mugs and serving trays made with this material don’t warp or fade when exposed to steam or sunlight for years. Offices, hotels, and school lunchrooms pick melamine for exactly these reasons: cheaper than porcelain, safer than glass, way easier to keep looking sharp without much effort.

The Drawbacks People Need to Know

Melamine doesn’t do everything. Put it in the microwave and you’ll find food barely warm but a dish that feels oddly hot. This material simply isn’t built for heating — subjecting it to powerful microwaves or oven heat risks breaking down the plastic and leaching chemicals. Some studies point out the potential health risks when people use melamine dishes for hot, acidic foods over long periods. The FDA established safety tests and limits — but folks might still wonder about long-term effects for their families.

Scratches and chips show up over time. Unlike stoneware or glass, you can’t toss a damaged melamine plate in the recycling bin in most cities. It sticks around for years in landfills if not properly recycled through specialized programs. Wait staff and parents know that after a few years, melamine’s once-glossy surface dulls, especially after repeated trips through commercial dishwashers.

Melamine Versus the Alternatives

Porcelain and glass have offered elegant solutions in the past. They feel hefty, look refined, and can handle a wider range of temperatures — straight from the freezer to the oven, no problem. If that plate breaks, though, sharp shards scatter everywhere. Not ideal with kids or in high-traffic cafeterias. Stainless steel, another popular alternative, handles both heat and cold but carries a higher up-front price and often lacks color and flair. Wood brings in a natural, appealing vibe, but it stains, cracks, and soaks up odors.

From a safety and health perspective, glass still gets my vote for reheating leftovers or serving acidic foods. There’s peace of mind in knowing it won’t react to microwave heat or tomato sauce. In allergy-prone households or places worried about chemicals, sticking with glass or stainless steel makes sense.

Smart Choices Going Forward

It’s easy to like melamine for sturdy everyday use, but knowing its limits matters. Avoiding microwaves, discarding chipped dishes, and limiting use with acidic foods lowers any health risk. Some manufacturers have started making recyclable melamine and phasing out dangerous chemicals in production, but the industry still has room to grow. Home cooks, school admins, and even design-forward restaurants can work together to demand safer products and help cities set up recycling programs for old melamine wares. For now, understanding both the strengths and weaknesses lets buyers pick the right material for their tables — and keeps dinner both safe and simple.

| Names | |

| Preferred IUPAC name | 1,3,5-Triazine-2,4,6-triamine |

| Other names |

1,3,5-Triazine-2,4,6-triamine

Cyanurotriamide Cyanuramide Aminotriazine |

| Pronunciation | /ˈmɛl.ə.miːn/ |

| Identifiers | |

| CAS Number | 108-78-1 |

| Beilstein Reference | 635822 |

| ChEBI | CHEBI:16881 |

| ChEMBL | CHEMBL1409 |

| ChemSpider | 5466 |

| DrugBank | DB03767 |

| ECHA InfoCard | EC Number: 203-615-4 |

| EC Number | 203-615-4 |

| Gmelin Reference | **88319** |

| KEGG | C01580 |

| MeSH | D008545 |

| PubChem CID | 7955 |

| RTECS number | PY5425000 |

| UNII | F939I1V6EM |

| UN number | 1267 |

| CompTox Dashboard (EPA) | DTXSID2020674 |

| Properties | |

| Chemical formula | C3H6N6 |

| Molar mass | 126.12 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.57 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | -1.37 |

| Vapor pressure | 0.02 mmHg (25 °C) |

| Acidity (pKa) | 5.0 |

| Basicity (pKb) | 9.0 |

| Magnetic susceptibility (χ) | χ = -64.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.662 |

| Viscosity | 10-30 mPa·s |

| Dipole moment | 1.13 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 143.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -239 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | −345.6 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V07AY13 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P261, P264, P270, P272, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 1-1-0-✱ |

| Autoignition temperature | 315°C |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD₅₀ (oral, rat): 3161 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Melamine: "3,161 mg/kg (oral, rat) |

| NIOSH | RN3796000 |

| PEL (Permissible) | 1 ppm |

| REL (Recommended) | 2.5 mg/kg bw |

| IDLH (Immediate danger) | 900 mg/m3 |

| Related compounds | |

| Related compounds |

Cyanuric acid

Ammeline Ammelide |