Propanal: Past, Properties, Practice, and Promise

Historical Development

Propanal, known to many as propionaldehyde, stepped onto the chemistry scene in the late 19th century, capturing interest for its straightforward structure and versatile behavior. Chemists relied on propanal as both a research tool and an industrial base chemical, exploring its reactions as soon as they had mastered basic distillation and synthesis. German and French labs published foundational methods using propanal as a test case for catalysis and oxidation. Factories across Europe recognized propanal as a stepping stone in the march to larger, more complex molecules, especially as new dyes, perfumes, and plasticizers entered the market. Manufacturing scaled up with the rise of hydroformylation—what people called the “oxo process”—pioneered by BASF, which churned out both propanal and its big cousin butyraldehyde. Propanal never became a household word, but in chemistry circles, it has held quiet importance for well over a hundred years.

Product Overview

Propanal belongs to the family of aldehydes—colorless, highly reactive, and packing a strong pungent odor. As a chemical building block, it supports a web of industries. From pharma to plastics, propanal tends to live behind the scenes. Its transparent appearance and watery fluidity belie a role in shaping flavors, manufacturing resins, and even crafting household products. Reliable suppliers provide it in bulk drums or secure tankers, always alert to its volatility and propensity to form peroxides under poor storage. Purity ranges match end-user demands, backed by batch-specific certificates and clear logistical support.

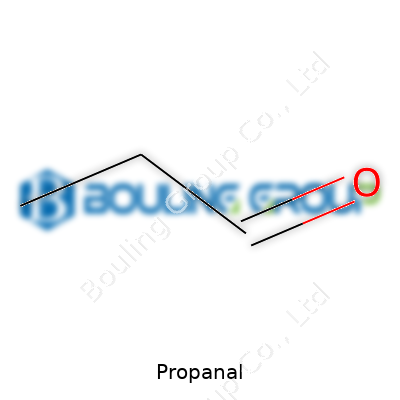

Physical & Chemical Properties

With the formula C3H6O, propanal lays out a simple linear structure: three carbons, with an aldehyde group at one end. The boiling point runs around 49°C, which means the stuff evaporates quickly unless sealed tight. Liquidity persists at most room temperatures, but frost creeps in below -81°C, when it freezes solid. With a specific gravity around 0.8 at room temperature, it’s lighter than water and floats atop if spilled into open tanks. That punchy, irritating odor stands as a warning for most, with low threshold for detection. Solubility stretches wide in ethanol and ether but stays modest in pure water. As an aldehyde, propanal brings a reactive hydrogen and carbonyl carbon to the table, setting the stage for addition, condensation, and polymerization reactions if left unattended.

Technical Specifications & Labeling

Every drum of propanal leaves a supplier with key technical markers spelled out: minimum purity—often 97% or better—levels of water, measurable acidity, and traces of peroxides get recorded. Industry norms require UN numbers, GHS pictograms, and careful hazard wording on each label. Quantities tick up from small bottles for research to tanks for production, and trace impurities can spell the difference between a smooth reaction and a sticky polymer mess. Details like CAS number 123-38-6, batch date, and storage guidelines appear on supply paperwork. Mishandling shows up first through peroxides, giving operators another reason to check dates and shelf life.

Preparation Method

Industrial propanal comes mainly from hydroformylation of ethylene, where catalysts—usually based on cobalt or rhodium—drive carbon monoxide and hydrogen into a mix with ethylene, forming both propanal and its isomer n-propyl alcohol. Older routes included oxidation of 1-propanol or controlled hydrogenation of acrolein, but these faded as hydroformylation proved efficient and scalable. Home laboratories may dabble with small-scale oxidation using manganese dioxide, but scale and safety kick in fast, with factories favoring closed systems and robust scrubbing methods to manage stray carbonyls and off-gas.

Chemical Reactions & Modifications

Propanal displays the classic aldehyde attitude, jumping into nucleophilic addition reactions at the carbonyl. Grignard reagents slide in to build alcohols, while reduction knocks the carbonyl down to n-propyl alcohol with little fuss using sodium borohydride or hydrogen plus nickel. Oxidation flips propanal into propionic acid through air or stronger agents like potassium permanganate. It undergoes aldol condensation with itself, yielding 2-methyl-2-pentenal, a step with both lab and commercial value. Derivatives branch out as chemists tailor protective groups or introduce aromatic partners through Friedel-Crafts or Wittig reactions. The carbonyl’s grip makes propanal versatile for both upstream and downstream synthesis.

Synonyms & Product Names

Ask for propanal in the lab and you’ll hear “propionaldehyde” or “methylacetaldehyde” as alternative names. International suppliers often list “propanaldehyde,” “Alonal,” or reference the IUPAC nomenclature directly. Catalogs and trade databases record all these aliases to ensure logistics don’t stumble on language or branding. Whatever the name, the structure—CH3CH2CHO—remains the constant, anchoring all discussions and documentation.

Safety & Operational Standards

Every handler grows cautious with propanal—its volatility and flammability keep teams alert at all stages. Flash point hovers below ambient, so fire safety requires grounded containers, explosion-proof vents, and full avoidance of open flames or sparks. Breathing in vapors leads to nose and throat irritation fast; chronic exposure never sits well for staff, bringing stricter monitoring and well-maintained ventilation. Gloves and goggles pull duty daily, with spill kits on hand for splashes. Storage containers lock down tight, away from oxidizers or acids, and teams learn to recognize the early hint of peroxide odors as a sign to check disposal logs. Emergency plans cover both environmental discharge and human exposure; suppliers share detailed SDS sheets covering all foreseeable scenarios.

Application Area

Manufacturing reaches for propanal as a starting block in varied industries. In plastics, it offers a precursor route into plasticizers, adhesives, and alkyd resins, smoothing the way for everyday products from coated papers to flexible packaging. The fragrance and flavor sector grabs purified propanal to craft artificial flavors and sharp notes for perfumes, often hiding behind the label of “aroma ingredients.” Agriculture and pharma producers convert propanal into herbicides and active pharmaceutical ingredients, where small molecular tweaks make all the difference. Research labs deploy it as a reagent or test molecule for exploring new synthetic routes, especially for more complex carbonyl chemistry. Some advanced applications even leverage propanal for fuel additives and specialty lubricants, drawing on both its volatility and reactivity to tune performance.

Research & Development

R&D teams pay close attention to propanal’s reaction chemistry, tracking new catalysts that speed up hydroformylation or fine-tune selectivity away from byproducts. Analytical chemists study its behavior in increasingly sensitive detectors, mapping traces down to the part-per-billion to meet food safety and environmental quality demands. Academic labs probe propanal’s value in “green” chemistry, searching for lower-emission routes to both the base chemical and its products. Research into its role in advanced materials—where propanal-derived monomers can offer self-healing or stimulus-responsive plastics—garner strong interest. Life-cycle studies look at upstream feedstocks, with bioethanol-derived ethylene now under review as a renewable input, mirroring larger carbon management efforts across the chemical industry.

Toxicity Research

Toxicology research on propanal points to an acute irritant profile, with exposure limits shaped by its volatility and aldehyde reactivity. Inhalation or skin contact brings discomfort fast, and repeated exposures—especially in unventilated workplaces—raise risk for coughing, red eyes, and potential sensitization. Rodent studies show limited systemic toxicity at doses far above workplace levels, yet chronic long-term risks remain under active monitoring, especially as aldehyde family members often flag for carcinogenicity investigations. Wastewater run-off from propanal production carries both odor and aquatic toxicity concerns; treatment plants stay vigilant for spills, and research continues into better scrubbing and catalytic oxidation solutions. Food industry studies focus on the safe limits where flavor applications use purified propanal or closely related derivatives, balancing intensity of aroma with clear toxicology data.

Future Prospects

Look ahead, and propanal sits at a crossroads. Interest grows in sustainable manufacturing, with pressure mounting for bio-based routes and closed-loop production. Next-generation catalysts, especially those cutting energy demands or lifting yields, open the door for more efficient output. Growth in specialty chemicals and advanced materials circles back to propanal as a flexible input—whether for new fragrance molecules, greener solvents, or specialty polymers. Regulations surrounding indoor air quality and chemical residues keep pushing R&D toward high-purity, low-residue versions. Process engineers focus on safety, aiming to minimize worker exposure and prevent environmental releases with every scale-up. Analysts forecast a steady if unspectacular market, with persistent value in dependable building blocks for society’s evolving chemical needs.

A Look at What Propanal Actually Does

Propanal rarely makes the headlines. Most folks wouldn’t recognize the name, but if you care about how things are made—from the glue that holds furniture together to the flavors in snack foods—this chemical deserves a closer look. Known as propionaldehyde to chemists, propanal is a colorless liquid with a sharp smell. It’s not the kind of thing you want to get on your hands, but it plays a part in a lot of things we use every day.

The Backbone of Many Chemical Processes

People often overlook the role of straightforward chemicals in the world of big industry. Propanal doesn’t get much attention compared to plastics or fuels, but factories use it as a starting point for making other products. Its biggest job sits in the production of other chemicals, especially propionic acid and trimethylolpropane. Propionic acid shows up in food preservatives. You see preservatives listed on a bread bag or in a block of cheese—odds are, some part of that came from propanal at the start of the chain.

Different industries turn to this chemical to churn out resins, plastics, and pharmaceuticals. Trimethylolpropane, made using propanal, gives flexibility to paints and coatings. I’ve worked around paint manufacturing, and seeing how one small molecule adds durability and shine to a can of paint always surprises me. Everyone likes a finish that lasts. The next time you open a paint can and the color still holds after a rainy month, remember chemicals like propanal help make that possible.

Where Flavor and Fragrance Start

Flavor creation teams search for raw ingredients that give foods appealing smells and tastes. Propanal hangs around the beginning of this process. Labs use it as a building block for creating fruity and nutty notes. Think about the synthetic flavors in snack chips or sodas; these owe some of their zing to molecules made from propanal. This doesn’t mean you should pour it on your food—pure propanal isn’t safe to eat or smell close up—but in tiny amounts, through the hands of experts, its byproducts jazz up a lot of what we eat and smell.

Why Safety Matters

Propanal doesn’t belong on a home shelf. It irritates the nose, eyes, and skin. Workers handling it suit up with gloves and goggles. Oversight comes from safety regulations, and companies monitor every step. I’ve seen what happens when people underestimate industrial chemicals; small mistakes lead to hospital trips. For anyone working in a place where propanal plays a role, constant training and up-to-date safety data sheets make the difference. Reliable labeling and clear instructions go a long way, but a culture that puts people’s well-being first gives the best protection. This isn’t just talk—scenarios play out differently where managers and workers know the risks.

Looking Toward Better Solutions

Chemical companies respond to pressure from regulators and customers to use safer or “greener” options when they can. Some move away from older technologies that release more hazardous byproducts. Improvement needs real effort at every level, from research labs to production lines. Propanal isn’t going anywhere in the short term, but smart choices about ventilation, waste handling, and spill response cut accidents. More research into alternative processes—sometimes using fermentation or renewable sources—offers hope that in the future, propanal’s job can be done with less risk to workers and the planet.

Understanding Propanal and Its Risks

Propanal shows up in plenty of labs and industrial settings. Folks working with solvents, flavorings, or certain plastics have likely crossed paths with this sharp-smelling liquid. Growing up around a family-run metal workshop, I saw how even small doses of chemicals can cause trouble if you ignore the labels or skip the gloves. Propanal, also called propionaldehyde, brings both benefits and risks. It can irritate eyes, skin, and lungs just from short-term exposure. Left open in a warm workshop, its fumes fill the air quickly. Long-term exposure ramps up the concerns, leading to headaches, dizziness, and in rare cases, possibly worse symptoms.

Real Experience, Real Precautions

Nobody in our shop claimed to be a chemist, but we respected what we didn’t know. The Material Safety Data Sheet (MSDS) on propanal leaves no doubt. Inhaling the vapor at high levels brings on throat burning and coughing; skin contact leaves red marks or even blisters. Propanal’s reputation for being highly flammable makes it a fire risk too. A spark or even hot metal can set it off. The National Institute for Occupational Safety and Health (NIOSH) marks it out for both health and safety reasons. Practicing safe handling feels less like a suggestion and more like common sense backed by hard data.

Industry Standards Can’t Be Ignored

Many industries look to OSHA guidelines for safety. Employers must keep vapor levels under 25 parts per million in the air and provide proper ventilation. Nothing beats a decent fume hood when you’re pouring this stuff. Even outside the lab, anyone using propanal should grab gloves—nitrile rubber works well—plus safety glasses and long sleeves. One factory tech I knew kept a fan pointed toward a vent every time he worked with aldehydes. Little habits like that can mean the difference between a safe shift and a hospital visit.

Respect for the Substance Builds Trust

Misinformation travels fast. Some folks claim using small amounts of propanal means there’s no need for precautions, since the risks sound “technical.” I’ve seen firsthand, though, how skipping steps leads to problems. Once, a coworker rinsed a spill carelessly, only to feel dizzy an hour later. Turns out, the room needed better airflow and a closed container. The CDC and EPA both track propanal as a volatile organic compound, reminding us that even trace amounts can hurt indoor air quality.

Improving Safety: Solutions from the Ground Up

Building a safer workspace takes more than just posters on the wall. Training makes the biggest difference. Staff who actually know what that sharp smell signals tend to act faster and smarter. Companies swapping open beakers for sealed containers keep accidents to a minimum. Spills cleaned with the right absorbents leave nothing to chance. Emergency showers, eye wash stations, and fire extinguishers near storage areas give peace of mind that comes in handy at the worst moment.

Personal Takeaway

Reading guidelines only gets someone halfway. Practicing them every day builds good habits. In my own work, double-checking storage lids and making sure labels face outward mattered as much as wearing gloves. Propanal delivers results for those who show respect—not just to the chemical, but to themselves and the people working beside them.

The Risks Lurking with Propanal

People working with chemicals usually know propanal as a sharp-smelling liquid used in labs or manufacturing. Underneath its simple, colorless appearance, propanal brings real risks. Flammable liquids don’t pull any punches when it comes to mishaps. Propanal catches fire easily from a tiny spark or a bit of static electricity, making storage a real issue.

Thermometers tell part of the story—propanal boils at just over 48°C, so a warm room already gets close to trouble territory. That means storing propanal away from heat sources, sunlight, and machinery that gets hot. When ventilation is poor, vapors build up, and exposure goes up. Anyone who has spent time in a stuffy chemical storeroom knows headaches and dizziness kick in fast in the wrong environment.

Storage Containers and Location

Glass or metal containers with tight-sealing caps serve best for holding propanal. Plastic occasionally reacts with strong solvents, and nobody wants to discover a leaking drum hours too late. Containers require clear labeling, including hazard pictograms. Mixing up containers in a rush can have rough consequences, especially in high-pressure jobs or during long shifts.

The storage area should sit far from any oxidizing or acidic substances. Mixing propanal with acids forms dangerous fumes, and oxidizers can trigger explosions. That’s not a theoretical risk—workplaces that overlook this have paid a heavy price with fires. Chemical safety guidelines from agencies like OSHA highlight separation routines and signage for one reason: Employees’ lives matter.

Containment and Spillage Plans

Leaks and spills demand immediate response. Propanal vaporizes quickly, so absorbent pads designed for chemical spills work better than standard shop rags. Any waste needs prompt and secure disposal. Personal experience in labs has underscored that spill drills, not just written plans, make a huge difference. If people know where the gear sits and how to use it, small mistakes don’t cascade into big disasters.

Backup containment, like spill trays and secondary barriers, can feel like overkill until something goes wrong. People may grumble about the extra steps, but there's no disputing that proper barriers breathe easier than facing an emergency cleanup.

Ventilation and Environmental Controls

Good ventilation isn’t just a luxury—without it, even a modest vapor release seeps into rooms and hallways. Fans, fume hoods, and exhaust systems keep air moving the right way. It’s not just about comfort; chronic inhalation of propanal can irritate lungs and eyes, and data from the CDC indicate long-term exposure contributes to worker illness.

Beyond health, protecting the wider environment means secure storerooms with floors designed to trap any accidental release. Her experience in industrial settings has shown that ignoring these designs can lead to expensive soil and groundwater cleanup.

Training and Ongoing Checks

No matter how strong a facility’s procedures sound on paper, regular training helps turn rules into reflexes. New staff, contractors, or even long-term employees need refreshers to keep standards high, especially if propanal isn’t the only hazard on site.

Routine inspections catch more than just expired labels and loose lids; they spot changes in storage temperature or wear on containers before bigger problems show up. Consistency beats emergency any day in chemical safety. Respecting what propanal can do creates a safer workplace—and a healthier team.

The Chemistry Baked Into Everyday Life

Propanal, also called propionaldehyde, carries the chemical formula C3H6O. That tiny combination of carbon, hydrogen, and oxygen tells a bigger story than a set of symbols ever could. Years ago, in my college organic chemistry lab, the sharp odor of propanal stood out even in a room full of strange smells. Its quick-to-react nature made glassware cleaning a real headache. But it also taught me how a simple aldehyde structure—basically a three-carbon chain ending in a carbonyl group—leads to a whole world of possibilities beyond textbooks.

The Real Role of Propanal Outside the Lab

Industry never ignores efficiency, so compounds like propanal end up everywhere we look. Plasticizers, preservatives, and ingredients for medicines start with molecules just like it. Its formula lines up with a logical order: three carbons straight, one oxygen double-bonded at the end, and everything else held together by six hydrogens. That structure lets it combine and react fast—so fast, in fact, that handling it safely becomes a top concern.

Take the paint and coatings field, for example. Here, propanal’s punchy reactivity supports quick-drying finishes and certain resins that keep surfaces strong. In pharmaceuticals, it marks the beginning of chains that eventually save lives. The food flavor industry also links to propanal, because its small, zippy structure helps simulate certain flavors—think green apples or a hint of fresh bread baking.

Why pick such a simple chemical as a workhorse? Its formula means factories can synthesize it at large scale without using rare ingredients. Producers turned to propanal in years past because the process, known as hydroformylation, built it from chemicals as basic as ethene (from petroleum) and a little synthesis know-how. As a result, industries could keep costs down while maintaining reliable supplies. That helps keep prices from swinging wildly for products most people use every day.

Health, Safety, and the Human Element

Ask any worker in a chemical plant—handling propanal without proper care spells trouble. Exposure means respiratory irritation or worse if left unchecked. I remember a friend who skipped gloves once, only to realize how quickly a bit of propanal can sting. Respect for the formula isn’t just about knowledge, but real-world consequences. Regulators demand air quality monitoring and proper training for a reason.

How to Tackle the Challenges

Chemistry in daily life brings problems that no formula can solve on its own. Producers put money into better ventilation, real-time sensors, and training that doesn’t just tick boxes, but actually gets people talking. Switching to closed systems for transferring propanal reduces leaks and exposures. The more investment in worker safety, the fewer surprises down the road—and the more trust builds between company and community.

The Power of Simplicity

Understanding propanal becomes a lesson in seeing design within nature and industry. Three carbons, six hydrogens, one oxygen—all arranged just so—build a backbone for so many materials that shape a modern life. Real science carries this blend of rigor, creativity, and responsibility that formulas alone never fully capture. Those symbols matter, but it’s people making choices with them that shape both industry and society.

A Close Look at Propanal’s Risks

Propanal, also called propionaldehyde, is a chemical that often sits quietly in industrial and lab settings. Its clear, sharp smell can catch you off guard, but the real trouble comes from more than just the fumes. People use it in making perfumes, flavorings, and plastics, thinking more about the product than the risks behind the scenes.

What Makes Propanal Risky

The first thing anybody notices is its volatility. Propanal evaporates fast, which means its vapors easily fill a work space. Breathing these vapors for any length of time irritates the eyes and nose quickly. Even in a well-ventilated area, spending an hour working with this stuff can leave your head pounding. Colleagues who forgot their masks used to complain their eyes burned for hours afterward.

The flammability can’t be ignored. A small spark, and it flashes up. I remember one technician tossing a rag after cleaning up a few drops—two minutes later, the trash can lit up. That’s not rare. The flash point sits low, and the vapors creep along benches, making them easy to miss. Many fires in older labs started with a careless spill of propanal and a bit of static.

Long-Term Health Effects

Short-term exposure tells only half the story. Skin contact might give a rash or redness, but regular exposure goes deeper than that. Over several years, folks constantly working with propanal are at higher risk for developing lung problems. Some early studies started connecting repeated, unprotected exposure to potential liver and kidney strain. While the links aren’t as solid as with other chemicals, doctors still watch for strange blood results in people who handle aldehydes for a living.

The trouble amplifies when small businesses skip proper protection. Faced with tight budgets or deadlines, workers sometimes handle open containers without gloves or goggles. A splash can turn into a day at the emergency room with chemical burns or respiratory swelling. People may think they’ll notice a spill right away—until exposure builds up slowly over weeks and the headaches and fatigue become a normal part of the job.

Keeping Workplaces Safer

Real solutions stick with basics. Direct exhaust ventilation does more to protect people than any fancy filter. Keeping containers sealed tightly and in proper lockers can stop many accidents from ever happening. Investing in basic chemical-resistant gloves and goggles turns out much cheaper than lost workdays or hospital bills. Training is just as essential—every new hire should walk through a safety drill before touching chemicals like propanal.

Storing propanal away from open flames and strong oxidizers removes a big piece of the accident puzzle. Simple spill kits under benches help reduce panic when a bottle tips—knowing what absorbs and neutralizes the liquid makes a huge difference. Back when we introduced yearly refresher courses, near-misses dropped by half, showing that hands-on practice sticks better than just memorizing a safety sheet.

Learning from the Past

Many stories about chemical safety get forgotten once a project ends, but the lessons stick with those who saw things go wrong. Propanal keeps showing up on hazard lists for good reason. Respecting its dangers, focusing on fresh air, good gloves, and sharp training pays off for both health and peace of mind. The folks who treat every chemical with care find themselves with far fewer stories about close calls—and a lot more years in the job.

| Names | |

| Preferred IUPAC name | propanal |

| Other names |

Propionaldehyde

Propional 1-Propanal Ethylcarbaldehyde Propionic aldehyde |

| Pronunciation | /ˈprəʊpən.æl/ |

| Identifiers | |

| CAS Number | 123-38-6 |

| 3D model (JSmol) | CC=O |

| Beilstein Reference | 1909224 |

| ChEBI | CHEBI:16905 |

| ChEMBL | CHEMBL16438 |

| ChemSpider | 7552 |

| DrugBank | DB01938 |

| ECHA InfoCard | ECHA InfoCard: 100.000.031 |

| EC Number | 200-852-0 |

| Gmelin Reference | 39394 |

| KEGG | C00156 |

| MeSH | D017209 |

| PubChem CID | 7847 |

| RTECS number | UC5950000 |

| UNII | Y4S76JWI15 |

| UN number | 1275 |

| Properties | |

| Chemical formula | C3H6O |

| Molar mass | 58.08 g/mol |

| Appearance | Colorless liquid |

| Odor | Pungent |

| Density | 0.8 g/cm³ |

| Solubility in water | miscible |

| log P | 0.59 |

| Vapor pressure | 3.54 kPa (20 °C) |

| Acidity (pKa) | 16.9 |

| Magnetic susceptibility (χ) | -32.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.384 |

| Viscosity | 0.407 mPa·s |

| Dipole moment | 2.52 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 160.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −200.6 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | −1521 kJ mol⁻¹ |

| Pharmacology | |

| ATC code | C01DX15 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H225, H319, H335 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P370+P378, P403+P235 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | -39 °C |

| Autoignition temperature | 208 °C (406 °F; 481 K) |

| Explosive limits | 2.1–15.3% (in air) |

| Lethal dose or concentration | LD50 (oral, rat): 1,650 mg/kg |

| LD50 (median dose) | LD50 (median dose): 1,500 mg/kg (rat, oral) |

| NIOSH | PA2450000 |

| PEL (Permissible) | 200 ppm |

| REL (Recommended) | 25 ppm |

| IDLH (Immediate danger) | 400 ppm |