Propyl Acetate: A Practical Look at What Makes This Compound Matter

Historical Development

Propyl acetate didn’t generate much excitement in its early days, yet it quietly shaped several industries. Chemists first identified it in the nineteenth century as they mapped out relationships among various esters. As industrial alcohol production picked up in the twentieth century, propyl acetate emerged as a practical solvent, easily synthesized from acetic acid and propanol. In an era when practicality often overruled aesthetics, this compound stepped up because it offered reliability and versatility. Over the decades, its presence grew across sectors like paints, coatings, and even food flavoring. Its story echoes the straightforward logic of chemistry: match a need with a solution, keep quality consistent, then refine and expand applications as industry evolves.

Product Overview

Propyl acetate’s value comes from its role as both a solvent and a flavoring agent. It carries a familiar scent, reminding most people of pears or rum, which made it a natural choice for artificial flavor creation. In paints and coatings, its evaporation rate sits right in the sweet spot—fast enough for productivity, slow enough to prevent issues like blushing or uneven coverage. Formulators trust it because it delivers repeatable results across batches. Companies handling everything from inks to lacquers hold this chemical in daily inventory, often under different brand names, but always counting on the same molecular structure.

Physical & Chemical Properties

With a molecular formula of C5H10O2, propyl acetate shows up as a colorless liquid, pleasant-smelling, and highly flammable. Its boiling point sits near 101°C, and its density measures about 0.89 g/cm³ at room temperature. Notable here is its low viscosity and modest polarity—it mixes well with organic solvents but refuses to play nice with water. This combination keeps it useful in industrial blending as well as laboratory research. The vapor gets noticed quickly, so ventilation and care always matter. People working with it rarely forget its strong, fruity aroma, a chemical calling card that hints at its presence from a distance.

Technical Specifications & Labeling

Anyone shipping or using propyl acetate pays close attention to purity, water content, and acidity. Technical grades must cross certain minimum purity thresholds, often above 99 percent. Labels show hazard symbols for flammability, and proper shipping names under international transport codes. Barcode systems track lot numbers, so tracing any issues doesn’t become a headache later on. Safety Data Sheets stay close at hand, backed by years of regulatory experience and chemical knowledge. Companies put effort into compliance because slips get expensive fast—one spill or mislabeling triggers investigations, fines, or worse. It pays to keep standards visible and understood, whether the end user runs a major manufacturing plant or a boutique fragrance studio.

Preparation Method

Factories typically produce propyl acetate by esterification, mixing propanol with acetic acid in the presence of an acid catalyst—usually sulfuric acid. The process demands control over temperature and water removal, since water nudges the reaction backward. Modern operations run continuous distillation to pull off the product, recycle unreacted starting materials, and achieve high yields. Plant operators keep an eye on column temperatures, flow rates, and catalyst activity so the chemistry keeps humming without hitches. I’ve seen old lab setups where students cooked batches gently in round-bottom flasks, each person learning firsthand why separation and drying processes matter once the reaction wraps up.

Chemical Reactions & Modifications

Propyl acetate behaves like a typical ester, standing up to bases and acids to a degree but eventually giving way during saponification or hydrolysis. Caustic soda turns it back into propanol and sodium acetate, which forms the backbone of several classic experiments. With strong acids or alcohols, transesterification can modify its structure, offering new compounds for niche applications. It generally stays unreactive during storage under normal conditions, making accidental byproducts rare. Anybody storing it near oxidizing agents or strong acids takes precautions, since unexpected chemistry sometimes follows poor housekeeping.

Synonyms & Product Names

Around labs and plants, people refer to this compound as propyl ethanoate, n-propyl acetate, or just “PA” in technical settings. Surface coatings may see it listed as NPA, and flavor manufacturers tag it “pear oil.” Each sector seems to coin its own shorthand, which creates confusion for newcomers but familiarity among seasoned workers. Regulatory filings pull these synonyms to ensure warehouses meet compliance across national and international guidelines.

Safety & Operational Standards

Handling propyl acetate starts with an understanding of its volatility and flammability. Spills evaporate fast, pushing workers to keep ignition sources out of the mixing bay. Adequate ventilation serves as the frontline defense against inhalation risks. Cartridge respirators and splash goggles come off the shelf any time large containers get opened. The flash point sits at about 14°C, so storage tanks look much like those used for solvents—bonded and grounded with vapor recovery in mind. Over the years, updates in global chemical safety laws forced manufacturers and users to raise their game, developing spill containment and fire response plans targeted specifically to this class of compounds.

Application Area

Look to surfaces that require even film formation—paints, varnishes, and wood finishes all count on propyl acetate’s predictable evaporation rate. Ink manufacturers add it to base blends for printing on porous materials, where fast drying without clogging stands as a constant demand. The flavor and fragrance world relies on purity, using food-grade batches to mimic the “pear note” in candies and beverages. Pharmaceutical labs sometimes exploit its solvency to carry active ingredients during the formulation process. Over the decades, each area found specific uses built around technical needs and sensory appeal, which speaks to the compound’s flexibility. While regulations on aromatics and solvents tightened, propyl acetate retained approvals for many roles—another reason it remains in steady demand.

Research & Development

Development teams consistently explore ways to boost production yield or reduce waste during synthesis. Biotechnological routes, such as engineered yeast strains, have entered the conversation within the last decade, promising lower energy requirements and fewer byproducts. Analytical chemists shifted focus to more sensitive detection methods in trace residue analysis. In my own lab experience, routine quality control tested both purity and volatility, and small improvements in distillation methods led to bulk savings at scale. Environmental scientists joined in, measuring fate in soil and groundwater, considering how shifts in process chemistry influence downstream risk or regulatory burden for manufacturers everywhere.

Toxicity Research

Toxicologists scrutinized propyl acetate as use spread, confirming that short-term exposure causes slight irritation to eyes or respiratory systems at high levels but breaks down quickly in living tissues. Chronic effects show up rarely, thanks to rapid clearance and minimal bioaccumulation. Most regulatory agencies set workplace exposure limits to keep air concentrations well below levels linked to irritation. Animal models give high safety margins, isolating its risk profile far below those of more reactive or persistent solvents. Despite a solid safety record, companies still enforce strict measures, since risk nearly always rises when bulk storage or large-scale handling enters the equation.

Future Prospects

Propyl acetate’s future closely follows the fortunes of sustainable chemistry. As the world looks to green solvents and renewable raw materials, biobased propyl acetate could take market share from petrochemical grades. Emerging applications in new inkjet technology, specialty adhesives, and even biotechnology show the chemical keeps earning its place. Regulatory compliance will tighten, favoring manufacturers who control emissions and demonstrate a shrinking environmental footprint. Research may soon deliver new synthesis routes with gentler catalysts and lower temperatures, making supply chains both cleaner and more reliable. In my view, this kind of practical, adaptable molecule always finds work—especially as industries evolve towards safer, smarter, and more sustainable processes.

Solvent Powerhouse in Paints and Coatings

A lot of people don’t think about what’s in the paint on their walls or the coating on their car. Propyl acetate turns up whenever a smooth finish needs quick drying. It breaks down resins and pigments better than a lot of other options. This leads to fewer streaks or bubbles, even if you're not a pro with a brush or spray gun. In years spent working on small renovation projects, I learned to look for paints that use this solvent, because cleanup gets a whole lot easier and the final coat dries in less time. In the coatings industry, propyl acetate matches the push for faster production lines. The faster the drying, the sooner a part makes its way to the next stage.

Breaking Down Inks and Printing

Walk into any print shop, and you’ll catch a distinct solvent smell—propyl acetate often plays a role. This solvent carries pigments in printing inks for magazines, food packaging, and labels. Print shops want their inks to set quickly on paper or plastic, which lets them push out job after job. Propyl acetate’s ability to carry ink evenly keeps the final image sharp. Anyone who has ever waited for a flyer to dry before stacking it in piles can appreciate the time (and money) saved.

Flavor and Fragrance Formulations

Not every use for propyl acetate is industrial. You’ll find it in the food industry and in perfume labs. Its fruity aroma turns it into a favored component for flavorings and fragrances, especially when manufacturers replicate apple, pear, or banana scents. A background in catering showed me just how many processed snacks and beverages draw from a library of hundreds of food-safe chemical compounds for taste and smell. Propyl acetate sits among the most popular thanks to its stability and mild flavor profile, which keeps the final product pleasant on the nose and palate, without overpowering.

Cleaning and Degreasing Jobs

Factories and repair shops often turn to propyl acetate for degreasing and cleaning jobs. Unlike harsh cleaners that corrode or leave residues, propyl acetate lifts oily residues from tools and machinery. As someone who’s spent weekends in a neighborhood auto shop, I saw how tough gunk on engine parts makes for a long job. Solvents like this make a difference, keeping equipment in working order and extending its life. This reduces the need to shell out for replacements or costly repairs.

Making Adhesives That Actually Stick

Adhesive manufacturers use propyl acetate to dissolve and mix chemicals for strong, flexible glues and sealants. This creates products that bond surfaces quickly, even in humid or varied temperature environments. I once helped a friend with woodworking projects, and he pointed out that solvents in construction adhesives affect how well two surfaces lock together. Propyl acetate featured on more than one can, especially for outdoor jobs that needed a bit of give without breaking apart in the cold.

Some Downsides and Chance for Better Safety

Every powerful solvent carries some risk. Propyl acetate gives off fumes that need good ventilation. Without it, headaches and eye irritation show up fast, especially in tight spaces. Industries have started using better air-handling systems and safety guidelines to keep workers healthy. Push for stricter safety labeling also means home renovators or hobbyists know to work with open windows and gloves. Upgrading workplace ventilation and raising awareness will help keep its benefits high and personal risk lower.

What is Propyl Acetate?

Propyl acetate turns up in a lot of industrial and consumer products. It brings a pear-like aroma and acts as a solvent in paints and coatings. Anyone who has walked through a freshly painted room or cracked open some nail polish has crossed paths with this stuff, often unknowingly. For people working in manufacturing, exposure can run higher compared to the average person.

Health Risks with Direct Exposure

No chemical deserves to be taken lightly, and propyl acetate doesn't break that rule. If you breathe in its vapor at high levels, it can irritate your eyes, nose, and throat. Extended contact or high vapor concentrations could bother your lungs and sometimes make you dizzy or give you headaches—symptoms you’d get from most organic solvents. I once spent an afternoon stripping old paint in a poorly ventilated room, thinking a dust mask would cut it. I quickly found myself feeling lightheaded, with watery eyes, and learned to respect the warning labels. Skin irritation can pop up if propyl acetate gets splashed on you; it draws moisture out of the skin, sometimes producing a mild rash or dryness.

Occupational Encounters

People who spend time around large amounts of propyl acetate—factory workers, paint sprayers, people in quality control labs—run the highest risk. In my own experience as a health and safety volunteer at a small manufacturer, some workers skipped the basics, trading gloves and goggles for speed. Respiratory complaints and eye redness followed before management invested in simple local exhaust systems and restocked the gloves bin.

The National Institute for Occupational Safety and Health (NIOSH) sets exposure limits to help workplaces keep their air in a safe range. Propyl acetate hasn’t been labeled as a carcinogen, but its ability to irritate and bother the body is well documented. Most regulatory agencies agree that brief, low-level contact won’t result in long-term health problems. The concern grows when people work in small, poorly ventilated spaces or handle it carelessly over time.

Consumer Goods and Everyday Risks

A home user faces much less risk than workers in constant contact. Nail polish and household adhesives contain low concentrations, and the brief exposure from occasional use isn’t likely to cause more than some mild, short-lived irritation (if any). Still, anyone with a respiratory condition such as asthma might feel effects sooner and should avoid breathing in fumes. Kids and pets, as always, deserve a wide berth from anything that smells sharp or comes in a bottle marked “flammable.” Keeping these out of reach and using products in well-ventilated spaces remains one of the smartest habits.

Managing Hazards: Smarter, Safer Practices

It’s possible to minimize risks. I recommend making ventilation your best friend—crack a window or run an exhaust fan when using products containing solvents. Gloves and protective eyewear don’t cost much and make a big difference for your comfort and safety. Store chemicals in their original packaging, well away from heat sources. Read every label, even if you’ve used the product before; manufacturers sometimes change formulas.

Employers have a bigger responsibility: supplying not just protective gear, but also honest training. Real, hands-on demonstrations and straightforward rules cut down on accidental exposure much better than a binder collecting dust. Workers who feel symptoms early—persistent cough, burning eyes, headaches—ought to step away, speak up, and see a healthcare provider if things linger.

One thing my work in health and safety taught me: people rarely regret taking time to protect themselves, but skipping precautions comes back to bite you fast.

Understanding the Chemical’s Behavior

Propyl acetate brings a fruity smell that’s easy to identify in factories and labs. It evaporates quickly, so sitting near an open drum easily fills the air with its odor. That same volatility gives clues about storage needs. Most solvents like this grab any chance to escape, so careless handling means fast evaporation and wasted product. Even more concerning, fumes collect and create a high risk for fire. NFPA rates propyl acetate as a Class IB flammable liquid, which signals to any worker that fire is a constant risk.

Limited Space, Smart Choices

I once watched a warehouse manager store barrels near open windows to vent those fruity fumes. He thought fresh air would help, but one exposed electrical switch nearby nearly spoiled the whole site. A tight lid and a solid safety plan saved the day, but no one wants that kind of adrenaline rush at work. That experience taught me to double-check locations and to respect the chemical’s volatility.

Any storage room needs full ventilation, and the temperature should stay below 30°C (86°F). The flash point of propyl acetate is just 14°C (57°F), so a minor spark or rise in heat could start something dangerous. Direct sunlight heats up a drum faster than many realize, so shaded indoor spots make more sense than outdoor cages or sheds unless those areas use fire-resistant materials.

Fireproofing and Chemical Segregation

If your facility works with other chemicals, avoid stashing acids and alkalis close to propyl acetate. Mixing these brings unplanned reactions, which anyone in safety knows to avoid. Workers sometimes rush through unloading or ignore chemical compatibility charts. It’s worth spending those few extra minutes to check; a simple printout on a wall saves time and headaches.

Sprinkler systems, flame arrestors, and dedicated spill containment trays keep accidents limited to one area. During my days maintaining a small manufacturing plant, I saw how quickly fire spreads when chemical drums sit in poorly maintained rooms. We switched to sealed metal containers with grounding wires. It wasn’t the cheapest fix, but after hearing the hissing of solvent fumes near a spark, nobody complained about the cost.

PPE and Emergency Prep

Handling the barrels or pouring from drums calls for chemical-resistant gloves and safety goggles. A splash looks harmless but burns just as fast as any harsher solvent, so small spills can’t be ignored. I always kept spill kits visible and trained staff in emergency procedures. Realistic drills matter more than any lecture. An eyewash station nearby offers backup if things go wrong.

Labeling and Inventory Tactics

Clear signage and proper labeling help everyone spot the risks at a glance. Some facilities skimp on this step, thinking workers already know what’s inside each drum. The day a new person joins is the day labels pay for themselves. Inventory tracking prevents accidental overstocking, limits old chemical build-up, and ensures everything gets rotated out before age causes stability issues.

Upholding Safety for Every Worker

Safe storage builds trust among workers and management. Stopping for quick checks, planning for worst-case scenarios, and keeping honest communication lines open matters more than any shortcut. Regulations set the lowest standard; real safety means going further, relying on personal vigilance, and learning from mistakes. Careful storage of propyl acetate creates a safer shop floor for everyone, every shift.

Understanding Propyl Acetate

Propyl acetate stands out as a familiar compound, especially for anyone who has worked around paints, coatings, or even nail polish remover. Many recognize its sweet, slightly pear-like scent. Chemically, propyl acetate is an ester, which means it results from the reaction between an alcohol and an acid—specifically, propanol and acetic acid in this case.

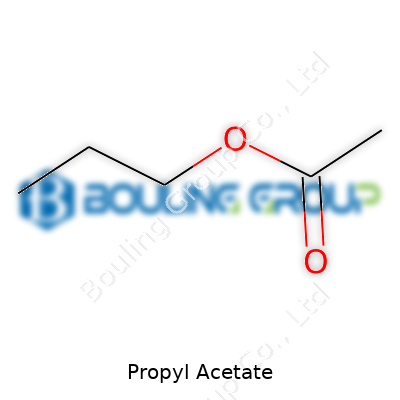

Chemical Formula and Structure

The chemical formula for propyl acetate is C5H10O2. Breaking that down, the structure reflects five carbon atoms, ten hydrogens, and two oxygens. The backbone includes a propyl group (three carbons in a chain) linked to an acetate group. Looking at its structural formula, it appears as CH3COOCH2CH2CH3. The acetate half (CH3COO-) links to the propyl side (CH2CH2CH3), showing that signature ester bond with an oxygen connected between the two parts.

I remember working in an undergraduate chemistry lab where we routinely synthesized esters like this for demonstration. Smells in the lab made it easy to guess which ester you made—propyl acetate’s fruity aroma almost always stood out, even if your glassware wasn’t perfectly clean. This clear connection between structure and properties struck me then, and has shaped my appreciation for organic molecules ever since.

Importance in Real-World Use

Propyl acetate shows up in many everyday items. Industries often add it to create that sought-after fruity note in perfumes or food flavorings—though, regulations clearly lay out safe usage levels. Its solvent power also explains its use in inks, coatings, and industrial cleaners. Compared to ethyl acetate, propyl acetate evaporates a bit more slowly, which can help balance drying times in paints and printed materials, allowing smoother finishes.

Safety comes up almost right away in discussions, especially among workers who handle large volumes. This compound moves quickly from liquid to vapor in open air. In closed rooms, vapors build up, so strong ventilation really matters. Inhaling high concentrations can irritate the eyes, nose, and throat—and in my time volunteering for a community safety group, I saw too many storage rooms lack basic airflow. Accidents tend to come from forgetting about these basics instead of misunderstanding chemistry.

Addressing Challenges and Promoting Safety

Not every shop floor or art studio installs expensive air extraction, but even propping open a window can help. Clear labeling and routine reminders go further than technical memos. Having talked with small print shop owners, I noticed that many got by with simple, honest hazard sheets and visible reminders about storing chemicals in cool, well-aired spots.

People sometimes assume that ingredients common in fragrances or food flavorings must always be safe at any dose. The lesson learned from propyl acetate—and really from every solvent—shows that dose and context matter. Public health authorities prioritize clear communication, and companies who embrace open safety discussions build trust both with workers and customers.

Closing Thoughts

Understanding the formula and structure of propyl acetate gives us more than just trivia for science class. It links chemistry to daily choices in industries covering everything from art to cleaning. Familiarity with core facts helps drive smarter decision-making, protecting workers and end users while bringing out the best in what this compound can offer.

What Propyl Acetate Brings to the Table

Propyl acetate pops up in everything from nail polish removers to printing inks. It’s great for making things dissolve and evaporate fast. The catch is, this stuff gives off vapors you don’t want in your body, and it catches fire easily. So, any workplace that keeps this solvent on hand needs a real plan, not just a dusty binder.

Why Quick Action Beats Complacency

Growing up around my uncle’s autobody shop, I saw more than one mystery puddle turn into a scramble when folks couldn’t recognize what spilled where. One time, a careless swipe at a small puddle with a shop rag led to complaints about headaches and nausea — typical signs of breathing in solvents like propyl acetate. Workers shrugged it off, but anybody stepping back could tell it wasn’t just a harmless mess.

Human Health Risks: Short and Long Term

Short-term exposure can whip up dizziness, throat irritation, or worse, put someone on the floor from breathing issues. The stuff can dry out or burn your skin. Longer term, folks dealing with repeated spills show early signs of chronic headaches and breathing trouble. Dropping the ball on cleanup or skipping the right gloves isn’t smart or safe. The National Institute for Occupational Safety and Health (NIOSH) signals that this isn’t just regulatory noise — the risks are real, and accidents add up over time.

Cleaning Up Without Compromising

Let’s get real: if someone spills, don’t just grab paper towels or toss some sawdust. The vapors spread fast, lighting up your air — and the inside of your nose — with that fruity, headache-inducing smell. Open windows if you’re inside. Wear splash goggles, nitrile gloves, and pull on a chemical-resistant apron before tackling the mess. If you don’t have gear for your lungs, step out and let the pros handle anything bigger than a splash.

Dust, sand, or commercial absorbents suck up a small spill quickly. Push the soiled material into a sealed metal drum, slap a label on it, and keep it somewhere safe until hazardous waste folks make a run. Never sweep it into a regular trash bin or rinse it down the nearest drain — both options risk setting off a fire or fouling up the water table.

Building a Smoother Response System

Too many shops leave safety training for new hires as boring lectures given once or twice a year. Show people how to spot and clean a propyl acetate spill right in the space where they’ll face it. Drill this muscle memory into daily routines. Hang the steps right above the workbench and keep gear in arm’s reach. Inspection checklists should include verifying the spill kit has dry absorbent, fresh gloves, and goggles that aren’t fogged up or missing a strap.

Thinking Beyond Quick Fixes

Switching to less volatile solvents works in some industries but isn’t always realistic. Making spill kits and safety gear part of someone’s everyday workflow keeps risk lower. Partnering with a local hazardous waste hauler means you won’t wonder what to do with a drum of soiled rags.

Any workplace blending, packaging, or using propyl acetate owes it to its people not just to stockpile solutions but to bake safety into the company culture. It keeps jobsites humming, bodies healthy, and business costs down by warding off serious accidents before they start.

| Names | |

| Preferred IUPAC name | Propyl ethanoate |

| Other names |

1-Acetoxypropane

1-Propyl acetate Acetic acid propyl ester N-Propyl acetate Propyl ethanoate |

| Pronunciation | /ˈproʊpɪl əˈsiːteɪt/ |

| Identifiers | |

| CAS Number | 109-60-4 |

| Beilstein Reference | 969234 |

| ChEBI | CHEBI:8786 |

| ChEMBL | CHEMBL140104 |

| ChemSpider | 5959 |

| DrugBank | DB02320 |

| ECHA InfoCard | 100.007.805 |

| EC Number | EC 204-689-0 |

| Gmelin Reference | 828 |

| KEGG | C01347 |

| MeSH | D011373 |

| PubChem CID | 8057 |

| RTECS number | AJ3675000 |

| UNII | YO838O76QQ |

| UN number | 1276 |

| Properties | |

| Chemical formula | C5H10O2 |

| Molar mass | 102.13 g/mol |

| Appearance | Colorless liquid |

| Odor | Pleasant, fruity odor |

| Density | 0.888 g/cm3 |

| Solubility in water | slightly soluble |

| log P | 0.97 |

| Vapor pressure | 24 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 25 |

| Magnetic susceptibility (χ) | '-47.8×10⁻⁶ cgs' |

| Refractive index (nD) | 1.394 |

| Viscosity | Viscosity: 0.72 mPa·s (20 °C) |

| Dipole moment | 1.88 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 229.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -449.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2431.7 kJ/mol |

| Pharmacology | |

| ATC code | D01AE24 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H225, H319, H336 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-3-0 |

| Flash point | 16 °C |

| Autoignition temperature | 460 °C |

| Explosive limits | 2.1–10.4% (in air) |

| Lethal dose or concentration | LD50 oral rat 9,370 mg/kg |

| LD50 (median dose) | LD50 (median dose): 9,370 mg/kg (rat, oral) |

| NIOSH | PAE2500000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Propyl Acetate: 200 ppm (840 mg/m³) |

| REL (Recommended) | 200 ppm |

| IDLH (Immediate danger) | 1700 ppm |

| Related compounds | |

| Related compounds |

Methyl acetate

Ethyl acetate Butyl acetate Isopropyl acetate Pentyl acetate |